Unless I'm working on loads for one of my Ruger #1s I don't find playing with seating depth of much value. Most of my rifles are limited by magazine length, so if you want to try and seat bullets out you're stuck shooting a single shot! What are you using for actions that allows you to seat bullets out is 30-06 based cases? For that matter I'm not able to seat VLDs out in my 7mm RM or 300 WM and we are talking jump in the .180" range. These may be great bullets but I don't want to stuff them that deep into the case.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature currently requires accessing the site using the built-in Safari browser.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Seating Depth

- Thread starter grry10

- Start date

joelkdouglas

Handloader

- Jun 5, 2011

- 1,310

- 3

I would recommend to start at magazine length and seat deeper. Berger has a good approach to seating depth, but it's not the only way.

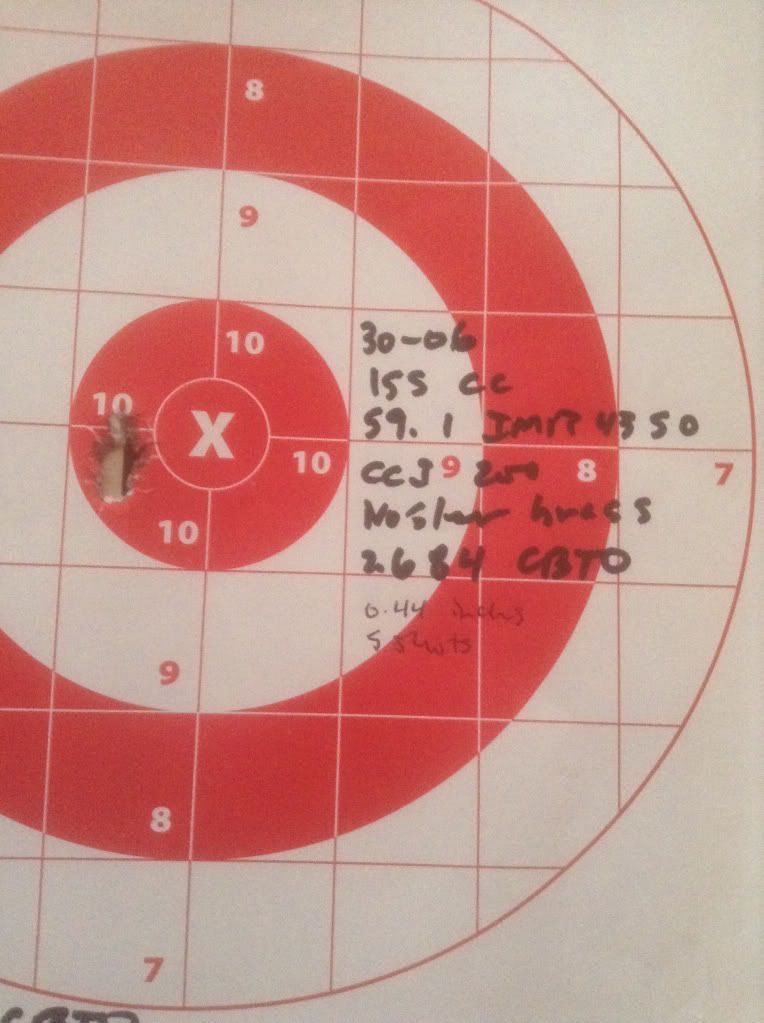

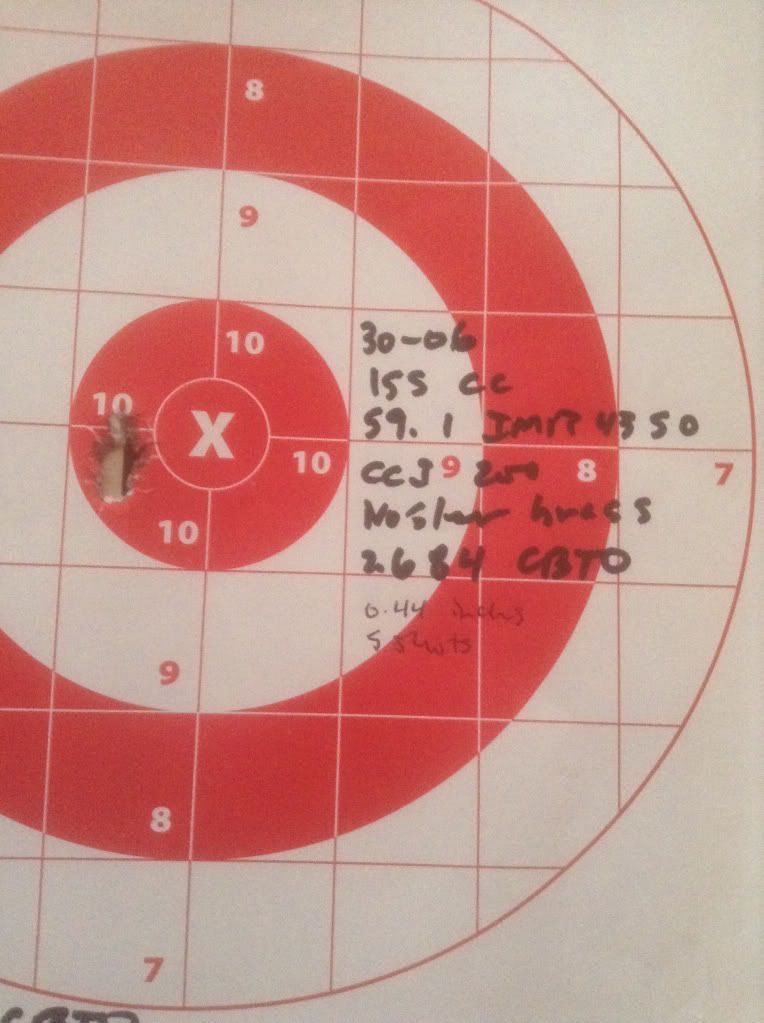

The below pictures are all the same load. It's for a 30-06, 59 grains IMR450, 155 Nosler Custom Competition, CCI 200 primer, Nosler brass. CBTO is cartridge base to ogive, but you can measure overall length instead. The ONLY change to these 3 pictures is seating depth in 0.005 increments. Top to bottom is 2.689 inches, then 2.684 inches, then 2.679 inches. All groups are 5 shot groups.

The below pictures are all the same load. It's for a 30-06, 59 grains IMR450, 155 Nosler Custom Competition, CCI 200 primer, Nosler brass. CBTO is cartridge base to ogive, but you can measure overall length instead. The ONLY change to these 3 pictures is seating depth in 0.005 increments. Top to bottom is 2.689 inches, then 2.684 inches, then 2.679 inches. All groups are 5 shot groups.

.300winmag

Handloader

- Oct 17, 2011

- 660

- 1

I've put Wyatt extended magazine boxes in my 700 actions before, lets me seat bullets out much further and not become single shots. I've even got a long throated .300 win mag for 215gr hybrids, it is loaded to over 3.600" OAL, lets me use the maximum case volume for powder and I can still feed them in my 700 with Wyatts bottom metal.

I can understand why you would feel that way.

I will have to differ though. I think seating depth is key. Without varying seating depth I just don't see how you can really bring a load in tight.

When I have a rifle rebarreled, or if it's a diy, the reamer or throating I look for is one that will work with my Magazine length.

On a factory chambered rifle instead of setting the rifle up for a particular bullet ot type of bullet, as above, I would try to choose a bullet that likes what I have to work with.

If the factory chamber and mag length leave me with a big jump then perhaps Barnes, the ABs or ABLRs, maybe Woodleighs or any other bullet that seems to do well with a big jump.

It seems, at least from my experiences, that the cup and core, many of the "target" or match bullets and sometimes the PTs do better with less jump.

I would think if you can find the nodes, which I believe are speed based, then run varying bullets at that speed, you'll find something that will work.

For what it's worth, here's the way I've been finding nodes recently.

I load, in smaller(sub 30) calibers, a single load at SAAMI COAL every .2 gr starting 1 1/2 to 2 gr under max. I leave the Magnetospeed attached to the rifle.(not worrying about accuracy yet). I shoot one of each and log the speed. What you are looking for is flat spots. Areas where .4 to even .8 gr difference shows very close to or the same speeds. That's a node. You should find two in the example used. I then look at the spread, say 51.0 gr to 51.8 gr and split it, in this case 51.4 gr. That's my load. Should be dead center of the node. Then I adjust seating depth. Should also allow for some temperature variations and still shoot well. It also allows you to find the nodes with a lot less shooting and rounds down the barrel, in this case between 10 and 20 rounds.

There's more but that's the basic way.

By the way, not my idea. It came from a guy that shoots competitively and I grabbed it and ran with it.

I will have to differ though. I think seating depth is key. Without varying seating depth I just don't see how you can really bring a load in tight.

When I have a rifle rebarreled, or if it's a diy, the reamer or throating I look for is one that will work with my Magazine length.

On a factory chambered rifle instead of setting the rifle up for a particular bullet ot type of bullet, as above, I would try to choose a bullet that likes what I have to work with.

If the factory chamber and mag length leave me with a big jump then perhaps Barnes, the ABs or ABLRs, maybe Woodleighs or any other bullet that seems to do well with a big jump.

It seems, at least from my experiences, that the cup and core, many of the "target" or match bullets and sometimes the PTs do better with less jump.

I would think if you can find the nodes, which I believe are speed based, then run varying bullets at that speed, you'll find something that will work.

For what it's worth, here's the way I've been finding nodes recently.

I load, in smaller(sub 30) calibers, a single load at SAAMI COAL every .2 gr starting 1 1/2 to 2 gr under max. I leave the Magnetospeed attached to the rifle.(not worrying about accuracy yet). I shoot one of each and log the speed. What you are looking for is flat spots. Areas where .4 to even .8 gr difference shows very close to or the same speeds. That's a node. You should find two in the example used. I then look at the spread, say 51.0 gr to 51.8 gr and split it, in this case 51.4 gr. That's my load. Should be dead center of the node. Then I adjust seating depth. Should also allow for some temperature variations and still shoot well. It also allows you to find the nodes with a lot less shooting and rounds down the barrel, in this case between 10 and 20 rounds.

There's more but that's the basic way.

By the way, not my idea. It came from a guy that shoots competitively and I grabbed it and ran with it.

joelkdouglas

Handloader

- Jun 5, 2011

- 1,310

- 3

pharmseller

Handloader

- Feb 13, 2012

- 550

- 79

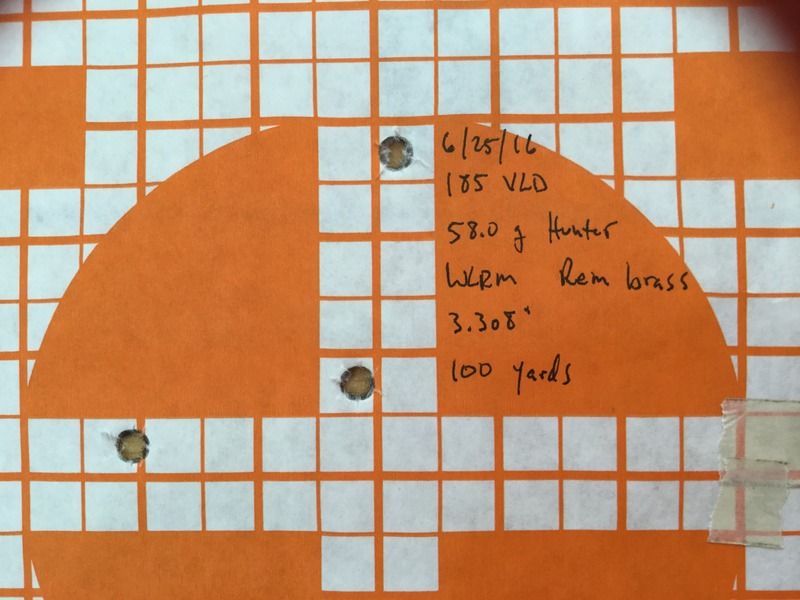

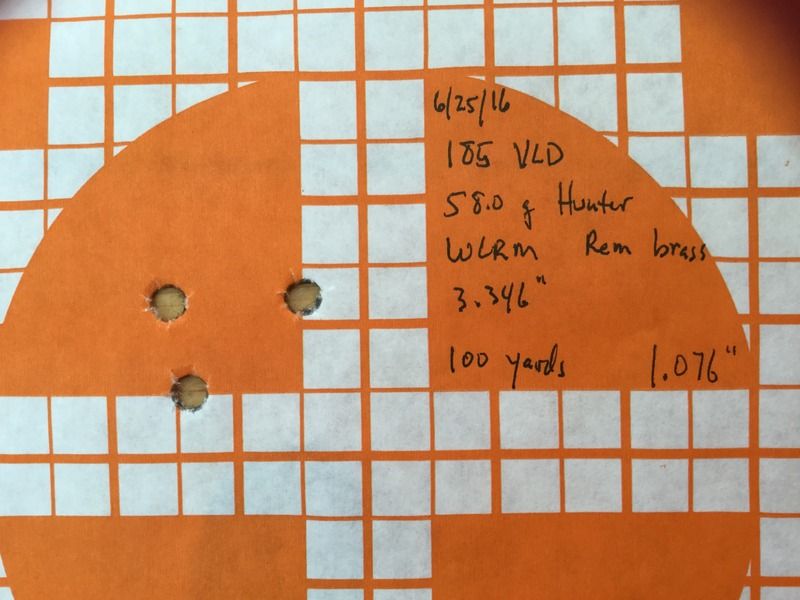

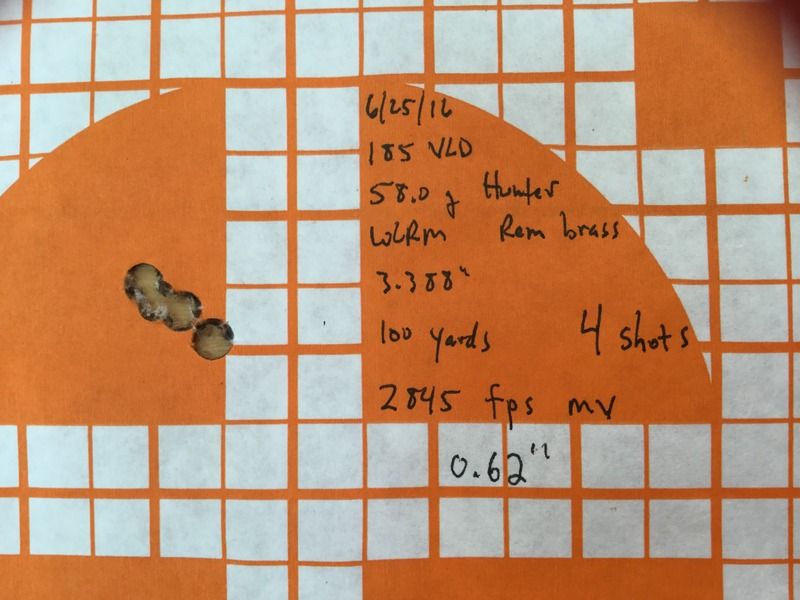

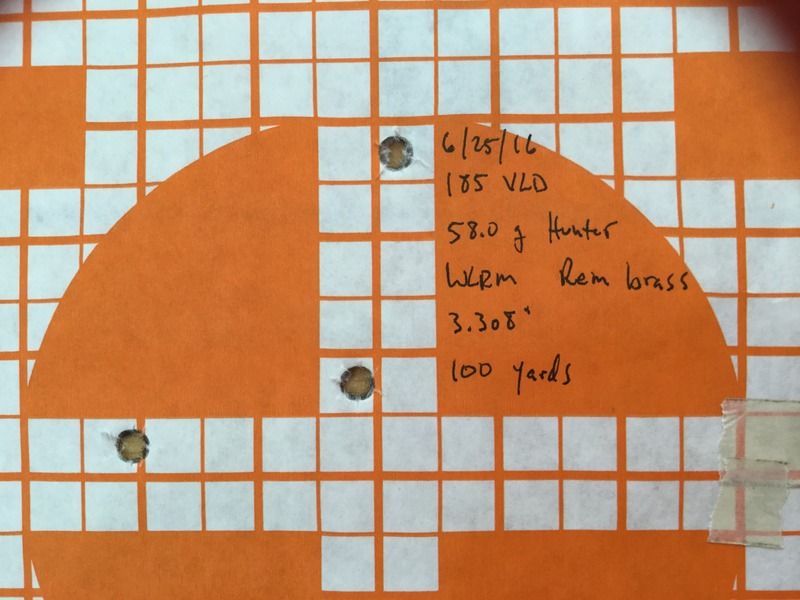

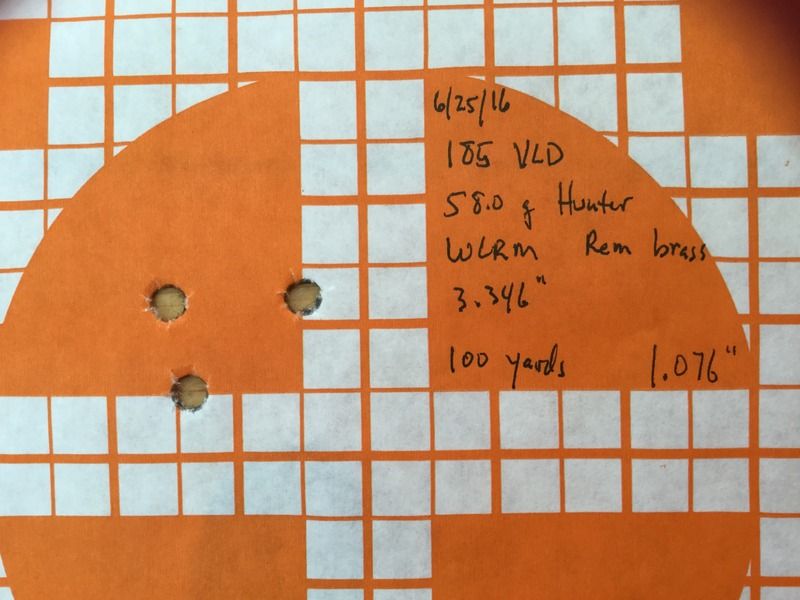

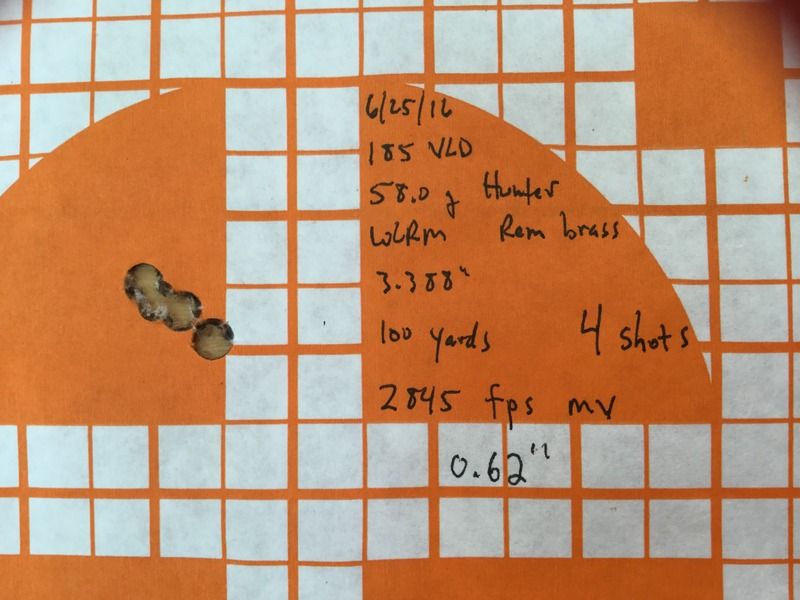

For me, seating depth is huge. I'll let the pictures tell the story.

P

P

Billyram

Beginner

- Oct 9, 2016

- 106

- 24

In my hunting / varmint rifles I like to seat the bullets .005"-.010" from the lands but have found with the tighter chambers in custom built rifles seating depth makes the least difference in accuracy. So I wouldn't worry too much about something you can't do much about and seat the bullets so the rounds feed reliably. Bullets, brass and powder make the biggest difference. When you hit on a good load seating depth, 1 grain powder difference won't make much difference in group size @ 100 yds.

Billy

Billy

TackDriver284

Handloader

- Feb 13, 2016

- 2,313

- 1,560

Dwh7271":aly1o131 said:Areas where .4 to even .8 gr difference shows very close to or the same speeds. That's a node. You should find two in the example used. I then look at the spread, say 51.0 gr to 51.8 gr and split it, in this case 51.4 gr. That's my load. Should be dead center of the node.

What is your range preference for this test?

My first ladder test was 300 yards and groups are pretty bunched up together, I assume 400 to 500 is ideal?

To get the speeds, you can shoot em in the dirt. :grin:

The first 10 or so (or however many it takes to go from your picked area to max)are only for velocity. I just shoot them at the target for practice. Because, in my case, the Magnetospeed is attached, there's a little p.o.i. shift, so I don't worry too much about how the target looks yet.

You're not looking for anything other than flat spots in velocity. Split the difference when you find one or two, then you shoot for accuracy. I'll load a couple or three groups of three with different seating depths and see what I have.

The first 10 or so (or however many it takes to go from your picked area to max)are only for velocity. I just shoot them at the target for practice. Because, in my case, the Magnetospeed is attached, there's a little p.o.i. shift, so I don't worry too much about how the target looks yet.

You're not looking for anything other than flat spots in velocity. Split the difference when you find one or two, then you shoot for accuracy. I'll load a couple or three groups of three with different seating depths and see what I have.