rodell

Handloader

- Dec 23, 2013

- 269

- 0

I've been working up a load for my Blaser 30-06 barrel and Nosler products.

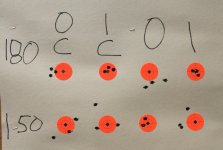

In this picture, the top row is 180 Accubonds and the bottom row is 150 Partitions. No sight adjustments were made, a minimum of two minutes between shots, minimal wind at the time of the shot and a distance of 100 yards. No scope adjustments were made. Each type was shot round-robin.

The AccuBond was .080" from the lands and the Partition .025" from the lands. Powder is the new Enduron IMR 4451 (approximately equivalent to H4350). The orange dots are 1.5",

I had both new Lapua cases that had been sized, and, once fired Lapua that had been sized. Both sized in the same die, using the same lube and press.

A "0" indicates a new case, and a "C" indicates the load was crimped with a Lee Factory Crimp die.

If nothing else, this test shows the importance of consistency when doing load development! Even small changes mean a lot.

(There is no third shot on the 150 line and the "0" column. The round failed to ignite - the primer failed. First one I've ever had. It burned, but very little and not enough to ignite the powder.) Too bad, I might have had a 150 PT load that had the same POI as a 180 load! I'll shoot it again when I have time.

In this picture, the top row is 180 Accubonds and the bottom row is 150 Partitions. No sight adjustments were made, a minimum of two minutes between shots, minimal wind at the time of the shot and a distance of 100 yards. No scope adjustments were made. Each type was shot round-robin.

The AccuBond was .080" from the lands and the Partition .025" from the lands. Powder is the new Enduron IMR 4451 (approximately equivalent to H4350). The orange dots are 1.5",

I had both new Lapua cases that had been sized, and, once fired Lapua that had been sized. Both sized in the same die, using the same lube and press.

A "0" indicates a new case, and a "C" indicates the load was crimped with a Lee Factory Crimp die.

If nothing else, this test shows the importance of consistency when doing load development! Even small changes mean a lot.

(There is no third shot on the 150 line and the "0" column. The round failed to ignite - the primer failed. First one I've ever had. It burned, but very little and not enough to ignite the powder.) Too bad, I might have had a 150 PT load that had the same POI as a 180 load! I'll shoot it again when I have time.