StoneHenge

Beginner

- Apr 6, 2017

- 5

- 0

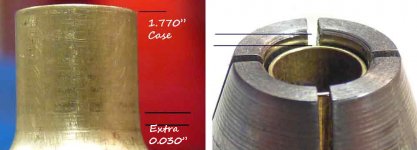

Rocketvapor, how long are the 75g Amax's? The Bergers I'm using are long and sit real deep loaded at 2.295 (c-products mag length is 2.32) and cycle fine. Don't get too caught up in the distance to lands, this is probably the second most accurate load I've ever come up with on paper at 100 yards - with the first being a 110 grain Varmageddon in my 308 RPR with an OAL of 2.60" that gave me a 0.16" 3 shot group while I was doing a ladder (SAAMI max OAL for 308 is 2.81")