Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: this_feature_currently_requires_accessing_site_using_safari

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

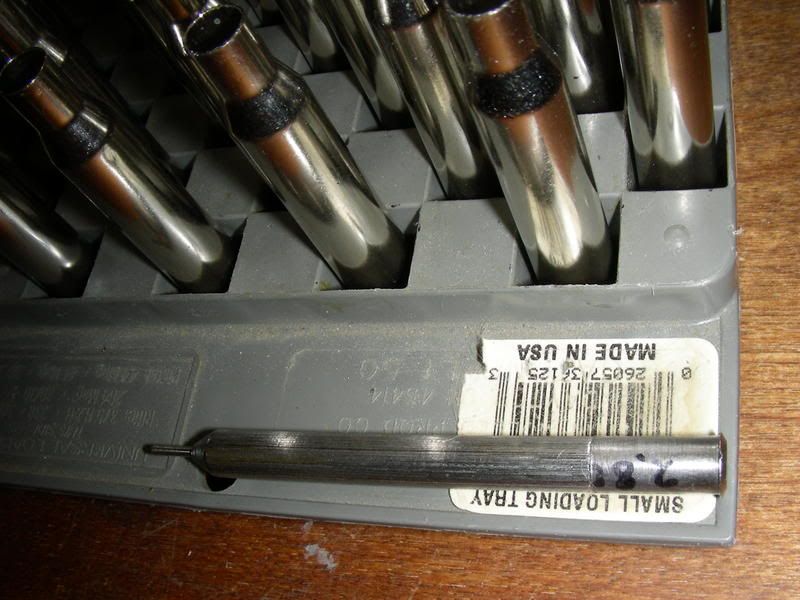

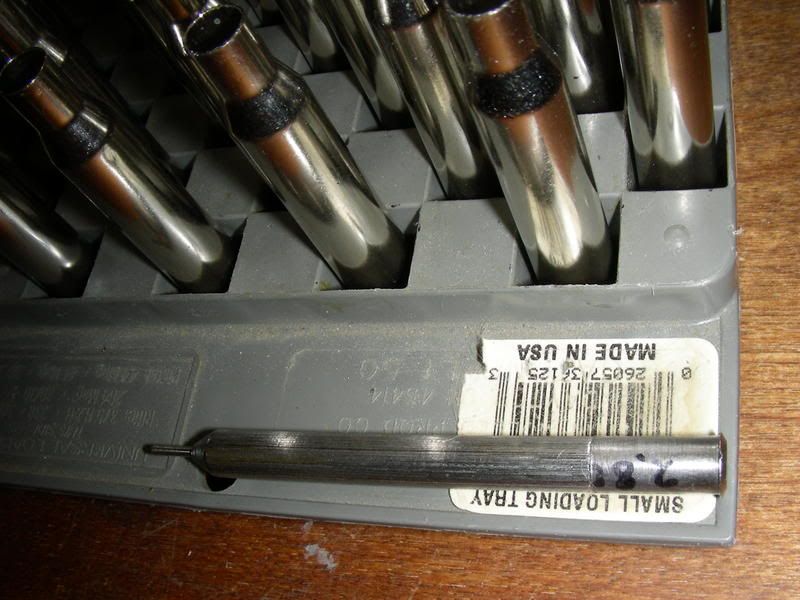

Brass ?

- Thread starter Co243Win

- Start date

- Oct 30, 2004

- 24,184

- 2,822

Personally I have found no difference. Even when I fireformed some to Ackley Improved.

sithlord6512

Beginner

- Nov 24, 2008

- 107

- 0

Cons,

Can't remember where I read it, possibly the gunwriters forum on the 24hourcampfire site, but one of the con's of nickle plated brass (If I remember correctly), is that it "flakes" off in the dies/chamber and is very difficult to remove. I will see if I can refind a link for you.

Can't remember where I read it, possibly the gunwriters forum on the 24hourcampfire site, but one of the con's of nickle plated brass (If I remember correctly), is that it "flakes" off in the dies/chamber and is very difficult to remove. I will see if I can refind a link for you.

sithlord6512

Beginner

- Nov 24, 2008

- 107

- 0

rick smith

Handloader

- Apr 6, 2005

- 1,249

- 0

Been loading it for years in both rifle and pistol, no problems. Old wives tales. Never ruined anything but a deers day.Rick.

- Oct 30, 2004

- 24,184

- 2,822

sithlord6512":34jn40cd said:Cons,

Can't remember where I read it, possibly the gunwriters forum on the 24hourcampfire site, but one of the con's of nickle plated brass (If I remember correctly), is that it "flakes" off in the dies/chamber and is very difficult to remove. I will see if I can refind a link for you.

This is why I brought up the fireforming issue. If it did not flake on this radical process then you're good.

- Nov 4, 2004

- 24,895

- 7,781

I have reloaded nickel plated cases for 22-250, 7x30 Waters and 300 Win Mag and have never had a problem.

JD338

JD338

Jim, you can always send them my way! I will put them to good use, I promise!

On another note, I have been reloading 270WSM WW nickel cases for a long time. I bought the rifle in Ca and never reloaded while I was stationed there, so I had about 10 boxes of the stuff (Winchester Supreme 140gr Accubonds), all empty. Well, I haven't bought cases yet for the WSM, and those Nickel 270WSM cases are holding up excellent! I have had one neck split with them. They clean up really well, are hard and haven't ever seen one flake. I like them alot actually, I will try to buy more when/if the time comes. Scotty

On another note, I have been reloading 270WSM WW nickel cases for a long time. I bought the rifle in Ca and never reloaded while I was stationed there, so I had about 10 boxes of the stuff (Winchester Supreme 140gr Accubonds), all empty. Well, I haven't bought cases yet for the WSM, and those Nickel 270WSM cases are holding up excellent! I have had one neck split with them. They clean up really well, are hard and haven't ever seen one flake. I like them alot actually, I will try to buy more when/if the time comes. Scotty

RiverRider

Handloader

- Dec 9, 2008

- 1,436

- 67

I have believed for a long time that nickel-plated brass is hard on case trimmer cutter heads. If I recall correctly, this was a conclusion I came to years ago when trimming some nickel-plated .357 Magnum brass and I have avoided all nickel-plated brass since.

DrMike

Ballistician

- Nov 8, 2006

- 37,169

- 5,631

Nickel plated cases are not my first choice. However, I do load the WW nickel plated cases for my 280. They work fine, and they are very attractive. They do flake somewhat, though I cannot say that this has proven detrimental to any sizing. RR is correct in that they are somewhat more brittle. Other than for my 280, I have a few 7mm RM cases and a few 300 WSM cases that I have collected from test loads, I usually do not use the nickel lated cases.

I have never had any problems with nickle cases in pistol brass except as mentioned they are hard to trim. I have had issues with them being brittle and hard to size. Of all the times I've had to remove a stuck case from a die, the majority of the time it has been nickle.

JT

JT

Nickel cases can cause problems. Reference this by Varmint Al

http://www.varmintal.net/arelo.htm#Nickel_Brass

One time the only brass in 280 rem I could find was nickel. Like with all new brass I run a Lee Collet through the necks to take out the dents and dings and to set bullet grip. Worked but it ruined the Lee Collet mandrel

Nickel case not for me!

http://www.varmintal.net/arelo.htm#Nickel_Brass

FORGET NICKEL-PLATED BRASS.... I liked the looks and feel of nickel-plated cases, but I don't load them anymore and here is why. The cases are strong and it is easy enough to outside neck turn them. That is not the problem. The nickel-plating on the case neck ID is like sandpaper. The only way you might be able to remove this grit is with a case neck ID reamer if you have a "tight neck" chamber and enough neck wall thickness to work with. If you have a loaded nickel-plated round laying around and don't believe me, just pull the bullet. It will look like you pulled it out of a tube of 180 grit wet/dry sandpaper. If you pull the bullet out of a brass case mouth that has been carefully chamfered and polished with the steel wool process above, it will be essentially like out of the bullet box. Want copper in the barrel? Start by sanding the surface of those nice polished precision bullets. Try it with a Moly Coated bullet and it is even worse; the nickel-plated cases scrape off the Moly. The nickel-plated case neck IDs don't get any better after you reload them a few times. They are still like sandpaper. Think about a few of those nickel pieces of grit imbedding into the copper of the bullet and what they do to your rifle barrel! I have heard that the nickel is hard enough to score some reloading dies and also wear down the expander ball. Any metal that hard, should be kept away from your precision barrel. I have heard that some people have had success in removing the nickel plate from the neck IDs with a stainless steel brush and a drill motor. I haven't tried it.

MORE ABOUT NICKEL PLATING.... This is interesting about the mechanical properties of the nickel plating:

Electrolysis nickel plating is a process for chemically applying nickel-alloy deposits onto metallic substrates using an auto catalytic immersion process without the use of electrical current. ...snip....

Hardness and Wear Resistance

One of the most important properties for many applications is hardness. As deposited, the micro-hardness of electrolysis nickel coatings is about 500 to 700 HK100. That is approximately equal to 45 to 58 HRC and equivalent to many hardened alloy steels. Heat treatment causes these alloys to precipitation harden and can produce hardness values as high as 1100 HK100, equal to most commercial hard chromium coatings. ...snip...

Note that if you anneal your nickel plated necks, you are hardening the nickel plating. It can be harder than many alloyed steels before you anneal and can increase is hardness as much as 2 fold by precipitation hardening. I sure wouldn't want those tiny little hard pieces inside the neck getting embedded in the bullet's copper surface and then fire lapping my nice shiny barrel.

One time the only brass in 280 rem I could find was nickel. Like with all new brass I run a Lee Collet through the necks to take out the dents and dings and to set bullet grip. Worked but it ruined the Lee Collet mandrel

Nickel case not for me!

Greetings RE. nickel plated brass. Since most of the replies have been inclined towards rifle cases I thought I would mention some ideas to be considered in regards to pistol cases. Nickel plating can cause hydrogen embritelment and the brass cannot be reloaded as many times as the plain variety. Seems like the crimping associated with the 44M wears out the cases ability to be reformed more than just a few times, resulting in split cases. Nickel being more susceptible to work hardening. Light loads seem to last much longer with the unplated cases in regards to splitting. At the price of these puppies it's worth getting the most {pardon} bang for your buck. Never had a problem with plated rifle brass however. This is also a concern in Drive shafts for custom cars/trucks that will be chrome plated, we Always increase wall thickness in the tubing {15-20%} for the hydrogen brittle factor. As the man says, there's my .02 and it's first hand. Newysan

Similar threads

- Replies

- 1

- Views

- 142