Well Gang, both my 700 Classic and my friend, Jim's Remington 673 in the 350JR wildcat arrived at our FFL today. It's only been "a few months" but, to say the least, its been a "trying time" for yours truly.

I hope, as I add to this thread that the end result is a bit more satisfying than it is at present. A few "things" did not end up as intended and I must point the blaming finger at myself, for the most part.

There is a bit of a dark cloud hovering on the project at this point but on the lighter side, there have also been a couple unexpected blessings that I previously was not aware of.

The rifle was purchased and went straight from the seller to the gunsmith chosen to set back and rechamber the 350 Rem mag in my brainstorm, the 350JR. A simple shortening, no other changes, of the original round, the 350 mag.

The photos shown to me, showed a very nice kept but very "blond" looking stock but the deal was struck and off she went to the gunsmith.

A full description of the round wanted, complete with NO other changes other than being shorter was discussed with the gunsmith. Same neck length of .355, no changes at all other than the shoulder being set back .375 inches and trimmed to 1.795. A "dummy" round of these dimensions from new brass had a case capacity of 58.7 grains of h20 and it was thought that perhaps, a slight gain on that would be gotten from fired and neck sized brass.

When the smith asked for the redding dies to be returned to him after he had shortened them to give the required length, I should have seen this big red flag waving at me but was assured the shoulder "had to be bumped JUST a bit" on the dummy rounds to get them to chamber.

In what universe a full .100 inch is a "bump", I don't know but the rifles arrived with the dies and some fired brass. A quick glance at such and I knew that the neck was "too long" and it is, because the shoulder on the round is set back considerably from the original plan.

At one point I had asked, repeatedly, to have the reamer spec sheet sent to me and was informed "he couldnt find it" and at this point, one is demanded but let's face it. It's too late.

I said from the beginning that a high end velocity round was not the GOAL but such is appreciated and Im less than tickled with a case capacity less than the original plans.

That said, I also can be quoted as saying "it is what it is" and it "will work" for our whitetail deer in Indiana, with room to spare but I'm just a little "nonplussed" about how the entire project has went and has ended.

Why a rifle barrel needs to be shortened 1.5 inches to be rechambered for a very similar round that is less than a half inch shorter than the original one, is beyond my capabilities of understanding and while again.........."it will work" a 20.5 inch barrel was not the intention. Praise the Lord I didnt send him a model SEVEN with the original 20 inch barrel!!! That came close to happening.

Another small "issue" is that the barrel on MY gun has not been recentered correctly and the sight holes are off to the right side about 1/4 inch.

The gunsmith made his best efforts to correct what he can by offering to pay for shipping to recenter the barrel (by making it shorter yet) and remove the 350 RM designation and label the barrel with "350JR" and pay return shipping out of his pocket.

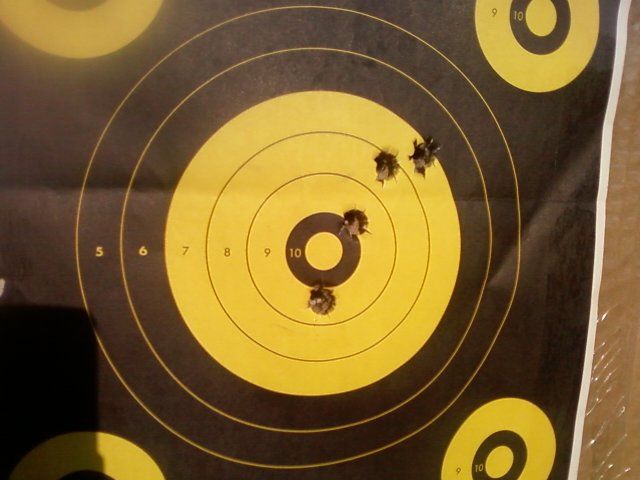

But, 60 brass are loaded with medium loads to half way zero the scopes, get in a little trigger time to familiarize ourselves with the rifles, and also to give us some 1x fired brass to work loads.

All said and done? I may have to go to faster burning powder should I want to "push the envelope" on bullet velocity. I now feel the powders on hand are capable of just filling the case and shoving a bullet in it but.......time will tell.

I'll post findings as I go but wish to take this time to thank ONE and ALL for the suggestions, help and advice along the road, for now........She's HERE, I'm LOADING and it's time to get set for SEASON!

God Bless!

Steve

I hope, as I add to this thread that the end result is a bit more satisfying than it is at present. A few "things" did not end up as intended and I must point the blaming finger at myself, for the most part.

There is a bit of a dark cloud hovering on the project at this point but on the lighter side, there have also been a couple unexpected blessings that I previously was not aware of.

The rifle was purchased and went straight from the seller to the gunsmith chosen to set back and rechamber the 350 Rem mag in my brainstorm, the 350JR. A simple shortening, no other changes, of the original round, the 350 mag.

The photos shown to me, showed a very nice kept but very "blond" looking stock but the deal was struck and off she went to the gunsmith.

A full description of the round wanted, complete with NO other changes other than being shorter was discussed with the gunsmith. Same neck length of .355, no changes at all other than the shoulder being set back .375 inches and trimmed to 1.795. A "dummy" round of these dimensions from new brass had a case capacity of 58.7 grains of h20 and it was thought that perhaps, a slight gain on that would be gotten from fired and neck sized brass.

When the smith asked for the redding dies to be returned to him after he had shortened them to give the required length, I should have seen this big red flag waving at me but was assured the shoulder "had to be bumped JUST a bit" on the dummy rounds to get them to chamber.

In what universe a full .100 inch is a "bump", I don't know but the rifles arrived with the dies and some fired brass. A quick glance at such and I knew that the neck was "too long" and it is, because the shoulder on the round is set back considerably from the original plan.

At one point I had asked, repeatedly, to have the reamer spec sheet sent to me and was informed "he couldnt find it" and at this point, one is demanded but let's face it. It's too late.

I said from the beginning that a high end velocity round was not the GOAL but such is appreciated and Im less than tickled with a case capacity less than the original plans.

That said, I also can be quoted as saying "it is what it is" and it "will work" for our whitetail deer in Indiana, with room to spare but I'm just a little "nonplussed" about how the entire project has went and has ended.

Why a rifle barrel needs to be shortened 1.5 inches to be rechambered for a very similar round that is less than a half inch shorter than the original one, is beyond my capabilities of understanding and while again.........."it will work" a 20.5 inch barrel was not the intention. Praise the Lord I didnt send him a model SEVEN with the original 20 inch barrel!!! That came close to happening.

Another small "issue" is that the barrel on MY gun has not been recentered correctly and the sight holes are off to the right side about 1/4 inch.

The gunsmith made his best efforts to correct what he can by offering to pay for shipping to recenter the barrel (by making it shorter yet) and remove the 350 RM designation and label the barrel with "350JR" and pay return shipping out of his pocket.

But, 60 brass are loaded with medium loads to half way zero the scopes, get in a little trigger time to familiarize ourselves with the rifles, and also to give us some 1x fired brass to work loads.

All said and done? I may have to go to faster burning powder should I want to "push the envelope" on bullet velocity. I now feel the powders on hand are capable of just filling the case and shoving a bullet in it but.......time will tell.

I'll post findings as I go but wish to take this time to thank ONE and ALL for the suggestions, help and advice along the road, for now........She's HERE, I'm LOADING and it's time to get set for SEASON!

God Bless!

Steve