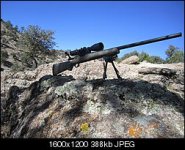

in the process for a new build up.-

stiller tac 30

Krieger barrel, ´

HS stock

jewell trigger

Graphite black cerakote

We finished with a .004¨ headspace

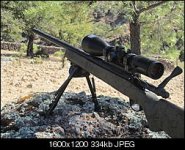

stiller tac 30

Krieger barrel, ´

HS stock

jewell trigger

Graphite black cerakote

We finished with a .004¨ headspace