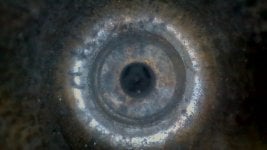

7x57 brass has been loaded 6 times. I don’t feel anything on the inside of the case to indicate any potential head separation.

I don’t load this rifle hot.

After the 5th load I neck sized for the sixth loading.

Worth annealing, load again or toss in the rejects pile.

Sent from my iPhone using Tapatalk

I don’t load this rifle hot.

After the 5th load I neck sized for the sixth loading.

Worth annealing, load again or toss in the rejects pile.

Sent from my iPhone using Tapatalk