Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: this_feature_currently_requires_accessing_site_using_safari

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Quality of Nosler 2nds

- Thread starter Richracer1

- Start date

Me too and I agree. If he has been a Nosler fan since '65, and is on that web site, .....why isnt he on here?Wally":3inynwpn said:I've reread the post several times. His test method seems to be lacking.........

Just my $.02,

Steve

- Thread starter

- #23

Richracer1

Handloader

- May 12, 2005

- 2,145

- 146

JusMo":1mubekv4 said:I think everyone here understands that Nosler 2nds are cosmetic blemishes only. If there are any weight tolerances out of spec then it was a mistake and we will make it good with the customer. Excellence, integrity, and service; those are three things that will never be compromised here. The only thing that anyone needs to do if they ever find a problem is to call us and we will take care of you. That's the way it has been since day one at Nosler and that's why a lot us, including myself, work here. I don't have an account over at the Cabelas website so if someone could please pass along this message it would be very much appreciated. Thanks guys. :grin:

I'll get it posted over there.

A

Anonymous

Guest

Thanks Rich.

It was also very nice to meet you in Salt Lake City. We'll be back at that show again next year in full force, make sure to mark it on your calendar and let us know if you can make it.

-Justin

It was also very nice to meet you in Salt Lake City. We'll be back at that show again next year in full force, make sure to mark it on your calendar and let us know if you can make it.

-Justin

- Thread starter

- #25

Richracer1

Handloader

- May 12, 2005

- 2,145

- 146

JusMo":2szu6sn5 said:Thanks Rich.

It was also very nice to meet you in Salt Lake City. We'll be back at that show again next year in full force, make sure to mark it on your calendar and let us know if you can make it.

-Justin

No problem, and it was good to meet you both as well. We'll see at that time, maybe I'll have a job by then. I'll be watching that thread to see what kind of replies that quote gets.

Same here, I have been following the Cabelas post also. I shoot pretty much all 2nds. I have a few boxes of firsts, but the availability of 2nds really drives what I shoot in my rifles.

I think the guy is a decent enough feller and found the same weight variance with other bullets, but it started with Nosler, so that is what people are hung up on. I don't shoot targets for score, just for accuracy in hunting rifles, so far, every Nosler I have loaded has been above and beyond my expectations, and most were MOA or under out to 300.

I think if some different powders were used, he may find a load that worked and it would have never came up, but he couldn't get one bullet to shoot so it made him investigate the bullets. HE found a little variance and thought it may have been because of that. He weighed other bullets also and saw just about the same thing. My smallest overall groups have been shot with Partitons, I cannot complain one iota. Scotty

I think the guy is a decent enough feller and found the same weight variance with other bullets, but it started with Nosler, so that is what people are hung up on. I don't shoot targets for score, just for accuracy in hunting rifles, so far, every Nosler I have loaded has been above and beyond my expectations, and most were MOA or under out to 300.

I think if some different powders were used, he may find a load that worked and it would have never came up, but he couldn't get one bullet to shoot so it made him investigate the bullets. HE found a little variance and thought it may have been because of that. He weighed other bullets also and saw just about the same thing. My smallest overall groups have been shot with Partitons, I cannot complain one iota. Scotty

Oldtrader3

Ammo Smith

- Nov 6, 2009

- 8,406

- 13

I, for the life of me, do not know how people can assign values like anger to my posts on the Cabelas Forum. I do not have time at this very moment to discuss my issues with Nosler seconds, but suffice to say that I am not angry just a 45 year customer of Nosler Partitions who has shot 1000's of them through the years and is one of your most loyal customers! It was my understanding that Nosler "Seconds" are not in process junk or sweepings off the floor, just cometic blemishes that do not affect performance. This has not been what I found and I will expound on it here later today. I am a retired Engineer BTW, and am not stupid or shallow.

In the meantime, if you wish to read all of the discussion before making up yor minds what it said, I would suggest doing so on th Cabala's Talk Forum

In the meantime, if you wish to read all of the discussion before making up yor minds what it said, I would suggest doing so on th Cabala's Talk Forum

- Nov 4, 2004

- 26,837

- 12,960

Oldtrader3

Welcome to the forum, glad you joined us here.

The factory seconds are over runs, tarnished jackets and irregular tips. They are always within weight spec of +/- .2 grains and of proper length. If you got something different, than it was sold in error.

I have been shooting seconds for years and use them for load development, target shooting and hunting.

Here is a recent group shot with a 7mm 140 gr BT seconds...

338 cal 250 gr AB seconds...

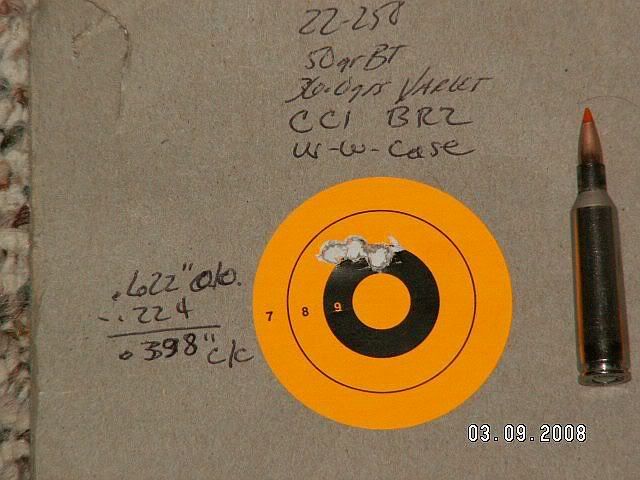

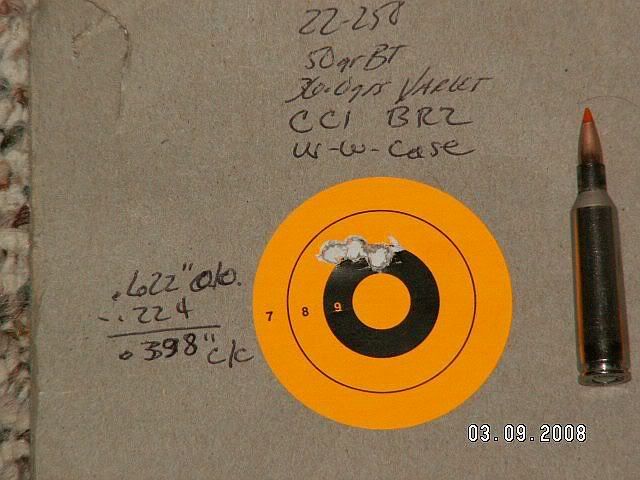

224 cal 50 gr BT seconds...

7mm 160 gr AB seconds...

338 cal 250 gr PT seconds, 4 shot group...

Seconds are just as consistent as the first.

Call Mike Harris at Nosler Customer Service and he will take good care of you.

JD338

Welcome to the forum, glad you joined us here.

The factory seconds are over runs, tarnished jackets and irregular tips. They are always within weight spec of +/- .2 grains and of proper length. If you got something different, than it was sold in error.

I have been shooting seconds for years and use them for load development, target shooting and hunting.

Here is a recent group shot with a 7mm 140 gr BT seconds...

338 cal 250 gr AB seconds...

224 cal 50 gr BT seconds...

7mm 160 gr AB seconds...

338 cal 250 gr PT seconds, 4 shot group...

Seconds are just as consistent as the first.

Call Mike Harris at Nosler Customer Service and he will take good care of you.

JD338

Oldtrader3

Ammo Smith

- Nov 6, 2009

- 8,406

- 13

Thank you for the welcome to your forum. I joined a while ago but serious health issues have kept me away until now. Below is some findings and conclusions, kind of summarized from the posts on the Cabaela's forum. I believe thaat they are self explanatory. Thank you for your time.

When I bought (4) bags of Nosler seconds, I expected blemishes and jacket discoloration. I did not expect the scale of process variation that I found without looking too hard. I have fired these bullets in two different rifles, a Mark V Weatherby .340 WM (1+ inch groups) and a Sako .338 Federal, which shoots 3/4 inch groups (what you would expect from a Sako). However, not with these Partitions! These bullets have never shot under 2+ inches in this accurate rifle with (3) different load development projects each and (6) different powders total.

That was what made me weigh the Partitions in the first place. I have not checked these bullets for diametral variation yet, but will. So after two rifles load developments and (6) powders tested in the (2) .338 calibers. I have fired about (100) Partitions Seconds in 210 grain and (25) Partitions in 225 grain (full price) and still don't have a reasonably accurate load.

I pulled a bag of Nosler 160 gr .284 Partition (seconds) to compare them to the 210 gr .338 Partitions (seconds) which I re sampled to check and make sure that the first sample was accurate. Here are the numbers:

Wgt: Dia: Low: High: Range: Mean: Sigma:

160 .284 158.3 159.7 1.4 gr 159.49 0.431

210 .338 209.7 211.0 1.3 gr 210.32 0.418

85 .243 000.0 000.0 0.3 gr. 85.160 0.097

Summary: the 160 gr .284 bullets are just as dispersed as the 210 gr .338 bullets are (almost, looking only at numbers). The standard deviations are similar (forget about degrees of freedom), the range of dispersion is also similar but .338 bullets have two outliers, vs. one for 7mm bullets. The bottom line is a older box (control group) of Partitions (85 gr .243 Partition) which represent what I normally would excpect from Nosler.

Both seconds have fliers that ruin any attempt to have accurate results without sorting prior to loading. The 7mm sample has one flier and the .338 sample has 2 fliers. Otherwise, populations and std. deviations are similar. Larger sample would reveal even greater dispersions because of mixed lots.

Differences: If I drop out the flier (158.3) from the 7mm bullets, the mean becomes 156.62 and the s=0.109. This means that the expected weight range drops to 159.3 to 159.9 (acceptable .6 total predicted popul. variation).

This is versus the .338 bullets which with the (2) fliers (211.0) dropped out the mean becomes 210.15 and the s=.245. This means that the expected weight range is still 209.4 to 210.9 gr. (still 1.5 gr total predicted popul. variation).

I did a test on the two groups and they were not similar which indicates that the both groups are out of control beut not similar (tri-variate and multi variate). I ordered a box of 210 Nosler bullets (not seconds) that are sample below. Compare this population to the Partition seconds.

These are small samples of small quantities (one box) of bullets and not too much should be read into these numbers but they, when compared to Ballistic Tip or AccuBond bullet samples are not encouraging regarding .338 diameter bullet manufacturing controls.

More data on the 210 Partition Noslers: I bought another box of off-the-dealer-shelf Nosler 210 Partitions. I pulled a sample of 30 bullets (to avoid degrees of freedom issues) out of 50 in the box and weighed each of the 30 bullets. I assumed that this would give me a good statistical characterization of at least this production lot of bullets and the ability to characterize them against the Partition "Seconds" that I spoke of earlier. Let me be clear about this entire subject. I have been lead to believe that "Seconds" of Nosler Partitions are for minor cosmetic defects and small deviance's from product for sale. To me this does not imply that you are buying the setup "shorts" and bullets swept off the floor from prior production lots. To me these would be bullets produced under normal production conditions that as far as QA Release in the production process and did not make the grade. Let me be clear about that!

Testing Results.

The 30 bullet sample of the off-the-shelf product had the following characteristics:

Mean Weight: 210.197

Range of measured Variance: 0.7 grains

Low Sample: 209.8

High Sample: 210.5

Standard Deviation (sigma): 0.187 grains

Predicted Population based on +/-3 sigma: 209.64 to 210.76 (1.12 grains variance)

Note:

1. Both the high and the low sample weights had (2) samples each with (3) samples 0.1 grain just above or below the sample limits.

2. Eleven of the 30 samples weighed 210.2 grains. The sample was multi-modal with (3) distinct population groups (high, middle and low). This grouping indicates a weak statistical control of manufacturing processes with no real process controls in force.

The 210 grain Partition (seconds) group is characterized as follows:

Mean Weight: 210.320 gr

Low Sample: 209.7

High Sample: 211.0 (2 samples)

Range of Measured Variance: 1.3 grains

Standard Deviation (s): 0.418

Predicted +/-3sigma population: 209.065 to 211.575

Note:

1. Distribution of samples is multi-modal and uniformly spread top to bottom.

2. Bottom 8 of 10 samples was within 0.7 grains (same as off-the-shelf product). Two samples weighed 211.0 grains.

Conclusions:

-Nosler has no formal Quality Plan with SPC (re: multi-modal distribution).

-I doubt that any SPC is being used to control setup and tooling dimensional variation. CpK would be predicted to equal less than 0.7, meaning no process control to forecast weight is presently either viable or predictable based on distribution frequencies.

-The Seconds group (except for two 211.0 grain exceptions) is the same in several attributes (ie. sample distribution and variance) as the production released off-the-shelf product. Even standard deviations would be similar if not for two "die setup" high flyers in the "seconds" mix.

-High flyers at 211.0 grains are most likely setup bullets made during final swaging die adjustment, prior to starting production run. They would likely be heavier (longer) than production weights.

-There is a correlation between length and weight as one would expect. The 211.0 gr product is 0.003 longer than any other sample.

-Off-the-shelf bullets show some attempt at trying to run production weights on the mode of the process limits. My sample only can predict process limits because of sample limitations to one lot of product.

-Normal production product variance is higher than I would expect but not outrageous at 0.7 grains

-Standard Deviation for production product is double the measured (s=approx. 0.09) of other lots of Nosler Partitions in sub .30 caliber products.

-Eleven bullets (36%) of the sample weighed 210.2 grains indicating that process can be better controlled.

Note: I have 6 pages of bullet sampling data and calculations (done by Excel) as backup if anyone is interested.

When I bought (4) bags of Nosler seconds, I expected blemishes and jacket discoloration. I did not expect the scale of process variation that I found without looking too hard. I have fired these bullets in two different rifles, a Mark V Weatherby .340 WM (1+ inch groups) and a Sako .338 Federal, which shoots 3/4 inch groups (what you would expect from a Sako). However, not with these Partitions! These bullets have never shot under 2+ inches in this accurate rifle with (3) different load development projects each and (6) different powders total.

That was what made me weigh the Partitions in the first place. I have not checked these bullets for diametral variation yet, but will. So after two rifles load developments and (6) powders tested in the (2) .338 calibers. I have fired about (100) Partitions Seconds in 210 grain and (25) Partitions in 225 grain (full price) and still don't have a reasonably accurate load.

I pulled a bag of Nosler 160 gr .284 Partition (seconds) to compare them to the 210 gr .338 Partitions (seconds) which I re sampled to check and make sure that the first sample was accurate. Here are the numbers:

Wgt: Dia: Low: High: Range: Mean: Sigma:

160 .284 158.3 159.7 1.4 gr 159.49 0.431

210 .338 209.7 211.0 1.3 gr 210.32 0.418

85 .243 000.0 000.0 0.3 gr. 85.160 0.097

Summary: the 160 gr .284 bullets are just as dispersed as the 210 gr .338 bullets are (almost, looking only at numbers). The standard deviations are similar (forget about degrees of freedom), the range of dispersion is also similar but .338 bullets have two outliers, vs. one for 7mm bullets. The bottom line is a older box (control group) of Partitions (85 gr .243 Partition) which represent what I normally would excpect from Nosler.

Both seconds have fliers that ruin any attempt to have accurate results without sorting prior to loading. The 7mm sample has one flier and the .338 sample has 2 fliers. Otherwise, populations and std. deviations are similar. Larger sample would reveal even greater dispersions because of mixed lots.

Differences: If I drop out the flier (158.3) from the 7mm bullets, the mean becomes 156.62 and the s=0.109. This means that the expected weight range drops to 159.3 to 159.9 (acceptable .6 total predicted popul. variation).

This is versus the .338 bullets which with the (2) fliers (211.0) dropped out the mean becomes 210.15 and the s=.245. This means that the expected weight range is still 209.4 to 210.9 gr. (still 1.5 gr total predicted popul. variation).

I did a test on the two groups and they were not similar which indicates that the both groups are out of control beut not similar (tri-variate and multi variate). I ordered a box of 210 Nosler bullets (not seconds) that are sample below. Compare this population to the Partition seconds.

These are small samples of small quantities (one box) of bullets and not too much should be read into these numbers but they, when compared to Ballistic Tip or AccuBond bullet samples are not encouraging regarding .338 diameter bullet manufacturing controls.

More data on the 210 Partition Noslers: I bought another box of off-the-dealer-shelf Nosler 210 Partitions. I pulled a sample of 30 bullets (to avoid degrees of freedom issues) out of 50 in the box and weighed each of the 30 bullets. I assumed that this would give me a good statistical characterization of at least this production lot of bullets and the ability to characterize them against the Partition "Seconds" that I spoke of earlier. Let me be clear about this entire subject. I have been lead to believe that "Seconds" of Nosler Partitions are for minor cosmetic defects and small deviance's from product for sale. To me this does not imply that you are buying the setup "shorts" and bullets swept off the floor from prior production lots. To me these would be bullets produced under normal production conditions that as far as QA Release in the production process and did not make the grade. Let me be clear about that!

Testing Results.

The 30 bullet sample of the off-the-shelf product had the following characteristics:

Mean Weight: 210.197

Range of measured Variance: 0.7 grains

Low Sample: 209.8

High Sample: 210.5

Standard Deviation (sigma): 0.187 grains

Predicted Population based on +/-3 sigma: 209.64 to 210.76 (1.12 grains variance)

Note:

1. Both the high and the low sample weights had (2) samples each with (3) samples 0.1 grain just above or below the sample limits.

2. Eleven of the 30 samples weighed 210.2 grains. The sample was multi-modal with (3) distinct population groups (high, middle and low). This grouping indicates a weak statistical control of manufacturing processes with no real process controls in force.

The 210 grain Partition (seconds) group is characterized as follows:

Mean Weight: 210.320 gr

Low Sample: 209.7

High Sample: 211.0 (2 samples)

Range of Measured Variance: 1.3 grains

Standard Deviation (s): 0.418

Predicted +/-3sigma population: 209.065 to 211.575

Note:

1. Distribution of samples is multi-modal and uniformly spread top to bottom.

2. Bottom 8 of 10 samples was within 0.7 grains (same as off-the-shelf product). Two samples weighed 211.0 grains.

Conclusions:

-Nosler has no formal Quality Plan with SPC (re: multi-modal distribution).

-I doubt that any SPC is being used to control setup and tooling dimensional variation. CpK would be predicted to equal less than 0.7, meaning no process control to forecast weight is presently either viable or predictable based on distribution frequencies.

-The Seconds group (except for two 211.0 grain exceptions) is the same in several attributes (ie. sample distribution and variance) as the production released off-the-shelf product. Even standard deviations would be similar if not for two "die setup" high flyers in the "seconds" mix.

-High flyers at 211.0 grains are most likely setup bullets made during final swaging die adjustment, prior to starting production run. They would likely be heavier (longer) than production weights.

-There is a correlation between length and weight as one would expect. The 211.0 gr product is 0.003 longer than any other sample.

-Off-the-shelf bullets show some attempt at trying to run production weights on the mode of the process limits. My sample only can predict process limits because of sample limitations to one lot of product.

-Normal production product variance is higher than I would expect but not outrageous at 0.7 grains

-Standard Deviation for production product is double the measured (s=approx. 0.09) of other lots of Nosler Partitions in sub .30 caliber products.

-Eleven bullets (36%) of the sample weighed 210.2 grains indicating that process can be better controlled.

Note: I have 6 pages of bullet sampling data and calculations (done by Excel) as backup if anyone is interested.

Oldtrader - Welcome to the forum, and thanks for your service.

Everybody here has read the Cabela's forum already and we don't really need to continue the same conversation here. Most of the shooters here use 2nds, and don't have any issues. I'm not saying that you didn't get a bad bag. It happens. I have had a bad box of firsts (tips eaten away by the cleaning solvet at the factory), I called up Nosler, and had a new box with in a few days. They are a first rate company and do everything they can to make things right. No compay is perfect, but you'll have a hard time finding anybody that has delt with Nosler customer service that wasn't happy with the way they got treated.

Give them a call and you'll see what I'm talking about.

Personally the 1.3 gr. range that you came up with only amounts for .0062% of the total bullet weight. That wouldn't bother me. Maybe your gun just doesn't like the 210 Partition. Just a thought.

Everybody here has read the Cabela's forum already and we don't really need to continue the same conversation here. Most of the shooters here use 2nds, and don't have any issues. I'm not saying that you didn't get a bad bag. It happens. I have had a bad box of firsts (tips eaten away by the cleaning solvet at the factory), I called up Nosler, and had a new box with in a few days. They are a first rate company and do everything they can to make things right. No compay is perfect, but you'll have a hard time finding anybody that has delt with Nosler customer service that wasn't happy with the way they got treated.

Give them a call and you'll see what I'm talking about.

Personally the 1.3 gr. range that you came up with only amounts for .0062% of the total bullet weight. That wouldn't bother me. Maybe your gun just doesn't like the 210 Partition. Just a thought.

Oldtrader3

Ammo Smith

- Nov 6, 2009

- 8,406

- 13

Thanks for the welcome. I was not sure where this forum stood on the posts , thanks. I have been very ill and was hospitalized until last Sunday for Toxic Shock and pneumonia (4th time this year in the hospital). Anyhow, I have been trying to recover and using this as a fill in to keep me active.

I will take samples from the other two seconds bags that I have not sampled next week. Since the 160 Partition 7mm bullets are the same variance range and sigma as the 210 gr .338's I will ask them to exchange them as well, I will call Nosler and discuss this with them ASAP. I do not believe that the 210 gr Partition will not shoot well in the two rifles (Bee Mark V and Sako Model 85) that have been tested with (3) IMR powders now and several loadings of each. Not when the rifles are both MOA class firearms with factory loads. In fact Sako quarantees it.

I have not been shooting the 160gr, 7mm bullets in my 7mm Rem Mag. I have been using CT Slilvertips in this rifle which group about 1 inch at 200 yards. I do not know how these seconds will shoot but the variance is way too much for my tastes, compared to what I have weighed in 7mm Nosler Partitions previously.

Anyhow, upward and onward with this project. I do believe that the 210's will shoot in both rifles because I get two approximately 1 inch groups 2.5 inches vertially apart in both rifles. and the bullets tend to test as bi-modal in weight. I will iron this out with weighed 210 bullets from the new box that I just bought. I am still committed to making the Partition work for me in the .338's.

I will take samples from the other two seconds bags that I have not sampled next week. Since the 160 Partition 7mm bullets are the same variance range and sigma as the 210 gr .338's I will ask them to exchange them as well, I will call Nosler and discuss this with them ASAP. I do not believe that the 210 gr Partition will not shoot well in the two rifles (Bee Mark V and Sako Model 85) that have been tested with (3) IMR powders now and several loadings of each. Not when the rifles are both MOA class firearms with factory loads. In fact Sako quarantees it.

I have not been shooting the 160gr, 7mm bullets in my 7mm Rem Mag. I have been using CT Slilvertips in this rifle which group about 1 inch at 200 yards. I do not know how these seconds will shoot but the variance is way too much for my tastes, compared to what I have weighed in 7mm Nosler Partitions previously.

Anyhow, upward and onward with this project. I do believe that the 210's will shoot in both rifles because I get two approximately 1 inch groups 2.5 inches vertially apart in both rifles. and the bullets tend to test as bi-modal in weight. I will iron this out with weighed 210 bullets from the new box that I just bought. I am still committed to making the Partition work for me in the .338's.

OT3, as stated earlier, Thank you for your Service.

I dont beleave anyone here disputes that you have found variances in your bullets, As Jmad said, it happens. Nosler customer service is number 1. you will get this problem resolved here.

And welcome to the forum! anything you can add will only be useful.

I dont beleave anyone here disputes that you have found variances in your bullets, As Jmad said, it happens. Nosler customer service is number 1. you will get this problem resolved here.

And welcome to the forum! anything you can add will only be useful.

Oldtrader3

Ammo Smith

- Nov 6, 2009

- 8,406

- 13

Nosler Partitions redux: I have changed the trigger on my Japanese Mark V (with it's hogged out, damaged MIM parts by former owners). I have installed a $110 Timney trigger and adjusted it to 2 pounds of crisp letoff, having to make new Steel(!!!) altered metric screw length and head diameters with my Dremel to hold it together.

The change is dramatic. My 225 gr Nosler load at 3100 fps, does not have flyers, 2 inches out, anymore and shoots 3/4 inch groups at 100 yards with weighed and sorted bullets. I am getting groups at or below 2.5 inches at 200 yards (with the wind and mirage-2-holes touching, one out) with the 250 gr Nosler AccuBond at 2900 fps.

The loads that I thought were giving me more variance are now the best loads, including the 210 grain Nosler Partition. My problem finally came down to replacement with good bullets, followed by eliminating flyers by losing the Japanese buggered trigger for a Timney.

This test is officially terminated.

The change is dramatic. My 225 gr Nosler load at 3100 fps, does not have flyers, 2 inches out, anymore and shoots 3/4 inch groups at 100 yards with weighed and sorted bullets. I am getting groups at or below 2.5 inches at 200 yards (with the wind and mirage-2-holes touching, one out) with the 250 gr Nosler AccuBond at 2900 fps.

The loads that I thought were giving me more variance are now the best loads, including the 210 grain Nosler Partition. My problem finally came down to replacement with good bullets, followed by eliminating flyers by losing the Japanese buggered trigger for a Timney.

This test is officially terminated.

- Nov 4, 2004

- 26,837

- 12,960

Oldtrader3

Glad to hear that everything has worked out well for you. :grin:

JD338

Glad to hear that everything has worked out well for you. :grin:

JD338

Wow., I would like to get the sampling data. What your background? Are in you QA? The other question that I have is what other bullets have you tested?Oldtrader3":27noq7ur said:Thank you for the welcome to your forum. I joined a while ago but serious health issues have kept me away until now. Below is some findings and conclusions, kind of summarized from the posts on the Cabaela's forum. I believe thaat they are self explanatory. Thank you for your time.

When I bought (4) bags of Nosler seconds, I expected blemishes and jacket discoloration. I did not expect the scale of process variation that I found without looking too hard. I have fired these bullets in two different rifles, a Mark V Weatherby .340 WM (1+ inch groups) and a Sako .338 Federal, which shoots 3/4 inch groups (what you would expect from a Sako). However, not with these Partitions! These bullets have never shot under 2+ inches in this accurate rifle with (3) different load development projects each and (6) different powders total.

That was what made me weigh the Partitions in the first place. I have not checked these bullets for diametral variation yet, but will. So after two rifles load developments and (6) powders tested in the (2) .338 calibers. I have fired about (100) Partitions Seconds in 210 grain and (25) Partitions in 225 grain (full price) and still don't have a reasonably accurate load.

I pulled a bag of Nosler 160 gr .284 Partition (seconds) to compare them to the 210 gr .338 Partitions (seconds) which I re sampled to check and make sure that the first sample was accurate. Here are the numbers:

Wgt: Dia: Low: High: Range: Mean: Sigma:

160 .284 158.3 159.7 1.4 gr 159.49 0.431

210 .338 209.7 211.0 1.3 gr 210.32 0.418

85 .243 000.0 000.0 0.3 gr. 85.160 0.097

Summary: the 160 gr .284 bullets are just as dispersed as the 210 gr .338 bullets are (almost, looking only at numbers). The standard deviations are similar (forget about degrees of freedom), the range of dispersion is also similar but .338 bullets have two outliers, vs. one for 7mm bullets. The bottom line is a older box (control group) of Partitions (85 gr .243 Partition) which represent what I normally would excpect from Nosler.

Both seconds have fliers that ruin any attempt to have accurate results without sorting prior to loading. The 7mm sample has one flier and the .338 sample has 2 fliers. Otherwise, populations and std. deviations are similar. Larger sample would reveal even greater dispersions because of mixed lots.

Differences: If I drop out the flier (158.3) from the 7mm bullets, the mean becomes 156.62 and the s=0.109. This means that the expected weight range drops to 159.3 to 159.9 (acceptable .6 total predicted popul. variation).

This is versus the .338 bullets which with the (2) fliers (211.0) dropped out the mean becomes 210.15 and the s=.245. This means that the expected weight range is still 209.4 to 210.9 gr. (still 1.5 gr total predicted popul. variation).

I did a test on the two groups and they were not similar which indicates that the both groups are out of control beut not similar (tri-variate and multi variate). I ordered a box of 210 Nosler bullets (not seconds) that are sample below. Compare this population to the Partition seconds.

These are small samples of small quantities (one box) of bullets and not too much should be read into these numbers but they, when compared to Ballistic Tip or AccuBond bullet samples are not encouraging regarding .338 diameter bullet manufacturing controls.

More data on the 210 Partition Noslers: I bought another box of off-the-dealer-shelf Nosler 210 Partitions. I pulled a sample of 30 bullets (to avoid degrees of freedom issues) out of 50 in the box and weighed each of the 30 bullets. I assumed that this would give me a good statistical characterization of at least this production lot of bullets and the ability to characterize them against the Partition "Seconds" that I spoke of earlier. Let me be clear about this entire subject. I have been lead to believe that "Seconds" of Nosler Partitions are for minor cosmetic defects and small deviance's from product for sale. To me this does not imply that you are buying the setup "shorts" and bullets swept off the floor from prior production lots. To me these would be bullets produced under normal production conditions that as far as QA Release in the production process and did not make the grade. Let me be clear about that!

Testing Results.

The 30 bullet sample of the off-the-shelf product had the following characteristics:

Mean Weight: 210.197

Range of measured Variance: 0.7 grains

Low Sample: 209.8

High Sample: 210.5

Standard Deviation (sigma): 0.187 grains

Predicted Population based on +/-3 sigma: 209.64 to 210.76 (1.12 grains variance)

Note:

1. Both the high and the low sample weights had (2) samples each with (3) samples 0.1 grain just above or below the sample limits.

2. Eleven of the 30 samples weighed 210.2 grains. The sample was multi-modal with (3) distinct population groups (high, middle and low). This grouping indicates a weak statistical control of manufacturing processes with no real process controls in force.

The 210 grain Partition (seconds) group is characterized as follows:

Mean Weight: 210.320 gr

Low Sample: 209.7

High Sample: 211.0 (2 samples)

Range of Measured Variance: 1.3 grains

Standard Deviation (s): 0.418

Predicted +/-3sigma population: 209.065 to 211.575

Note:

1. Distribution of samples is multi-modal and uniformly spread top to bottom.

2. Bottom 8 of 10 samples was within 0.7 grains (same as off-the-shelf product). Two samples weighed 211.0 grains.

Conclusions:

-Nosler has no formal Quality Plan with SPC (re: multi-modal distribution).

-I doubt that any SPC is being used to control setup and tooling dimensional variation. CpK would be predicted to equal less than 0.7, meaning no process control to forecast weight is presently either viable or predictable based on distribution frequencies.

-The Seconds group (except for two 211.0 grain exceptions) is the same in several attributes (ie. sample distribution and variance) as the production released off-the-shelf product. Even standard deviations would be similar if not for two "die setup" high flyers in the "seconds" mix.

-High flyers at 211.0 grains are most likely setup bullets made during final swaging die adjustment, prior to starting production run. They would likely be heavier (longer) than production weights.

-There is a correlation between length and weight as one would expect. The 211.0 gr product is 0.003 longer than any other sample.

-Off-the-shelf bullets show some attempt at trying to run production weights on the mode of the process limits. My sample only can predict process limits because of sample limitations to one lot of product.

-Normal production product variance is higher than I would expect but not outrageous at 0.7 grains

-Standard Deviation for production product is double the measured (s=approx. 0.09) of other lots of Nosler Partitions in sub .30 caliber products.

-Eleven bullets (36%) of the sample weighed 210.2 grains indicating that process can be better controlled.

Note: I have 6 pages of bullet sampling data and calculations (done by Excel) as backup if anyone is interested.

As for my own samples. I find bullets to be a little less in range, and multimodal. I see a larger issue in brass... My guess is that we are getting multiple lots in each box. However, I am not privy to any data or processes that Nosler uses in manufacturing. Last comment, Even with the variances, I see some mighty fine groups and once I settle on a load, I can consistently shoot 5 shot groups under 1 inch in factory guns, Bees, only guaranteed to show groups of 3 at 1.5 inches with cold barrels.

thanks and welcome,

Hardpan

Oldtrader3

Ammo Smith

- Nov 6, 2009

- 8,406

- 13

Thanks, guys. Hardpan, I was Director of Worldwide Manufacturing Operations for 15 years and managed 10 plants in 8 countries in Medical Device, IV Infusion Products that I did all the strategic manufacturing planning for. Prior to that I was a Plastics Molding/Tooling, Automation and Packaging Equipment Engineer/Manager, whatever, for 25 years. Every is ISO9001 buttoned down with SPC and lot history/traceablity. Dealing with the FDA in 8 countries and all. I also worked for a pharma. giant.

I had 120 engineeers in 5 groups working for me at one time and I was Plant Manuf. Director of a 1500 man plant. Plus I have an MBA. I am old and decrepit now and have bad health but a good brain is trapped in a failing body. All this means nothing as I am old and retired now.

I had 120 engineeers in 5 groups working for me at one time and I was Plant Manuf. Director of a 1500 man plant. Plus I have an MBA. I am old and decrepit now and have bad health but a good brain is trapped in a failing body. All this means nothing as I am old and retired now.

Oldtrader3":3afriy17 said:Thanks, guys. Hardpan, I was Director of Worldwide Manufacturing Operations for 15 years and managed 10 plants in 8 countries in Medical Device, IV Infusion Products that I did all the strategic manufacturing planning for. Prior to that I was a Plastics Molding/Tooling, Automation and Packaging Equipment Engineer/Manager, whatever, for 25 years. Every is ISO9001 buttoned down with SPC and lot history/traceablity. Dealing with the FDA in 8 countries and all. I also worked for a pharma. giant.

I had 120 engineeers in 5 groups working for me at one time and I was Plant Manuf. Director of a 1500 man plant. Plus I have an MBA. I am old and decrepit now and have bad health but a good brain is trapped in a failing body. All this means nothing as I am old and retired now.

Why am I not surprised? thanks.

Oldtrader3

Ammo Smith

- Nov 6, 2009

- 8,406

- 13

beretzs":2u1uom6f said:You sound like you are doing okay OT3, cause as much as you bang away with that 340, you have to have some good life left in ya!! That rifle might handle recoil well, but it still isn't for the faint of heart! Scotty

That old Japanese-banger, Mark V keeps getting better which motivates me to push it out there more and see what it can do. This caliber has always been the ultimate .33 for me. I have the 210 Partitions running at over 3150 now and with pretty good accuracy. They may be only .400 BC but they fly well and group well.

Or course, now there are other big .33's like your edge. I was offered a Remington 700, Lapua setup really cheap and turned it down. There is not enough difference to convince me that I want another one. Plus two premium brass stocks for loading were one too many for me.

I bought some bedding glass compound for the stock of this Mark V (it does not fit right). They tab bedded it and the tab is falling apart on the RH side. Someone needs to find out what they do in process that makes cheap Tupperware stocks always touch on the right channel???

Thanks, Hardpan, you don't stop being an engineer just because you retire. You just no longer get paid for it.

Similar threads

- Replies

- 5

- Views

- 272

- Replies

- 11

- Views

- 407