Ever since I've had my P64 338 Win Mag it's been a horrible copper fouling beast. I really didn't care too much but my problem with it was it would take 7-10 rounds just to settle back down after a good cleaning. I can hear a few saying "what's the problem, just don't clean it". Well, I really didn't unless I really was letting it sit for awhile. I DBC'ed and that had actually helped a lot but it would still take a bunch of shooting to get it to settle down after a decent cleaning. Plus, as all of know and feel sometimes, you just gotta try and work it :lol:

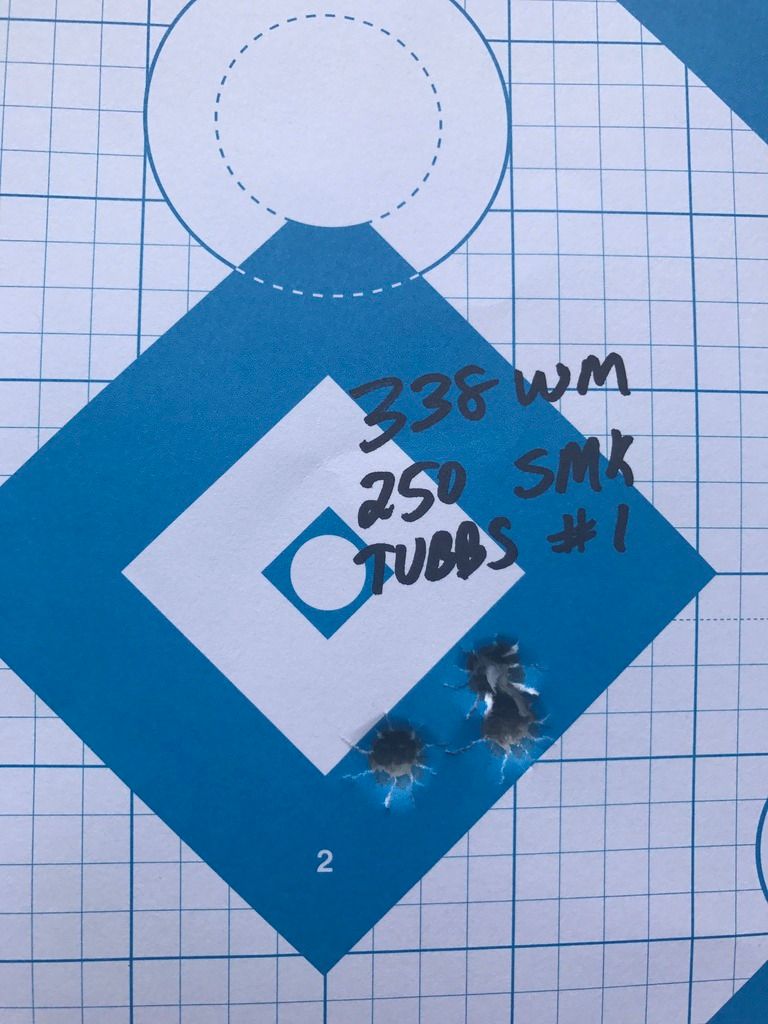

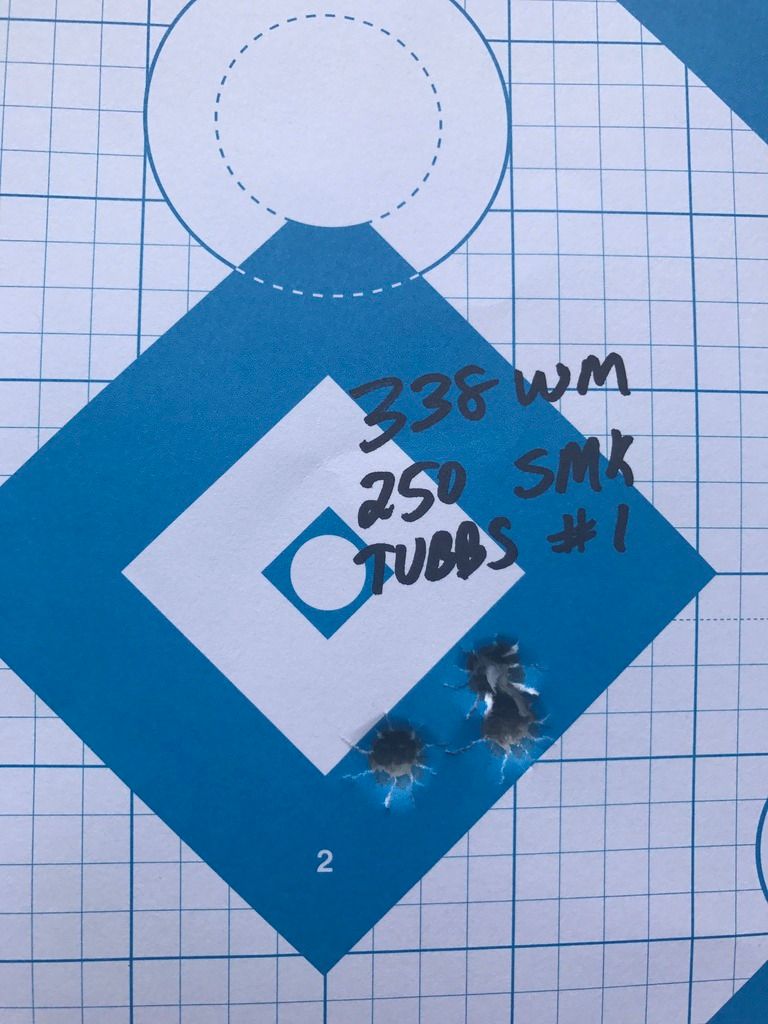

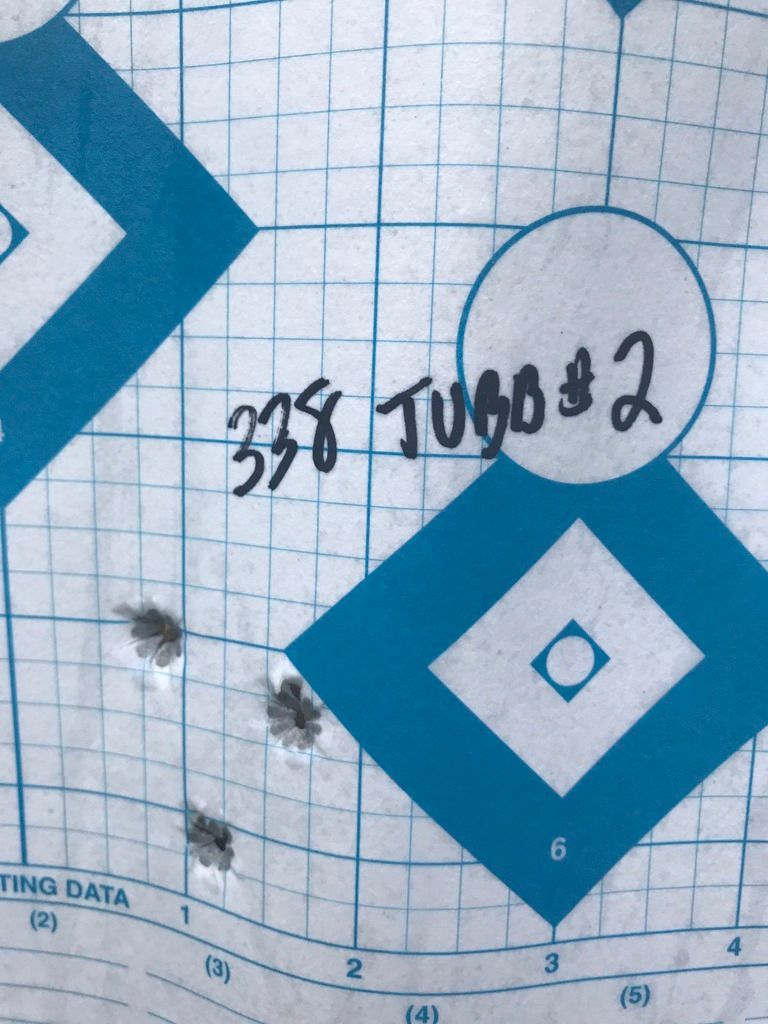

Well, Tubbs comes with 50 bullets, from a course starting bullet to a final burnishing bullet. 10 each of them. You're supposed to use a minimal load. They was as little deformation of the bullet as possible in order to knock down high spots. I used the lowest book load for IMR4350 I could find for a 250 grain bullet since they provide what looked like Sierra Matchkings in the kit. I loaded them up and shot the first ten. True to form the first 3-4 were all over. Then shots 5 on started coming together.

I didn't take a picture of the rest but they all clustered right in there. After the first 10 I cleaned it and noticed it felt smoother and it cleaned up much faster.

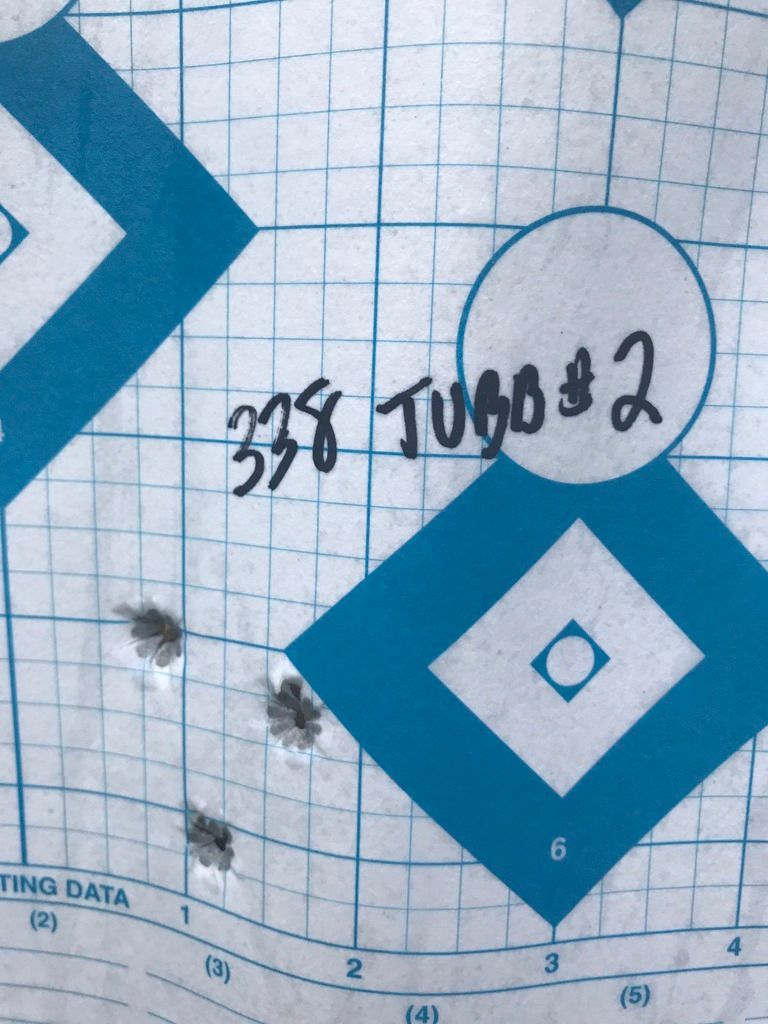

These are actually 3-5 from treatment #2. Again I didn't take a picture of all 10 but it was promising. Cleaned again, smoother and easier.

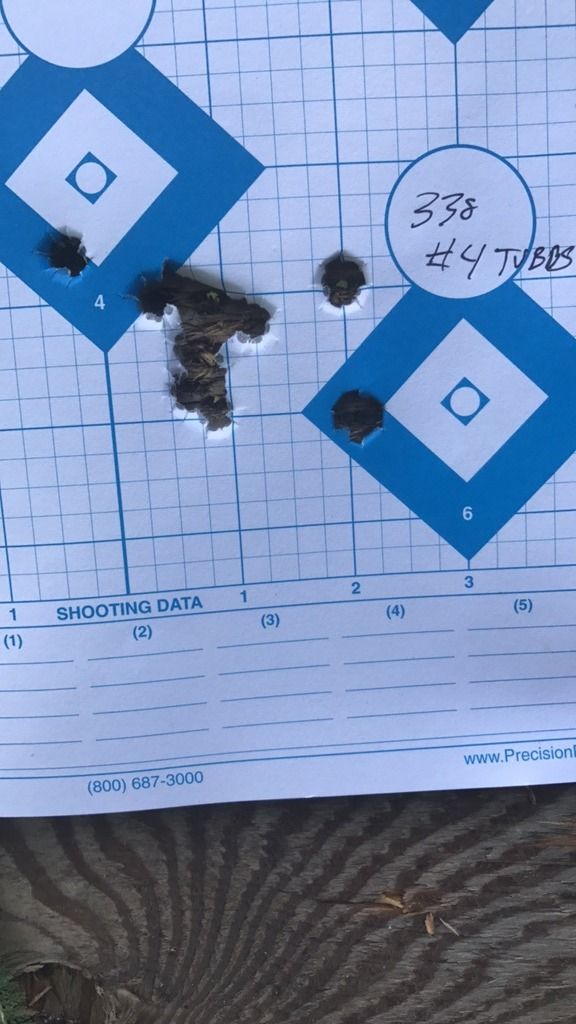

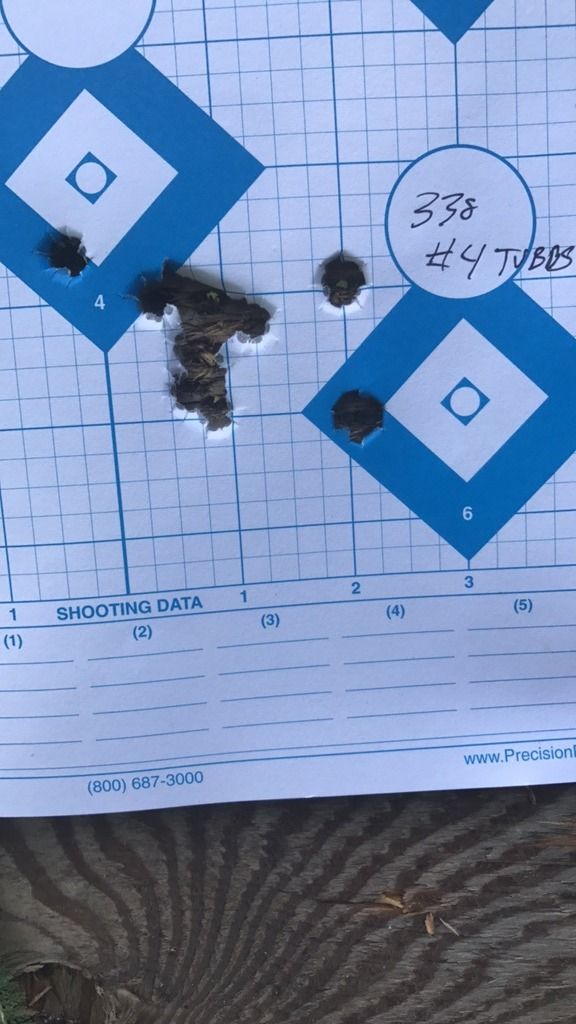

This one they are all staying relatively close. At least better.

Now we are talking. I actually started getting excited. This is the best the rifle has even done from a bare steel barrel.

That's the last 10 and there is the tiniest copper streaking. Right now I've got the barrel soaking with copper killer and once it's clean I'll DBC it again. I'm thinking I've got it about as good as I can get it.

So, if you have a rough barrel you don't wanna get rid of, give them a try. They aren't expensive and if you have the time they seem to help.

Well, Tubbs comes with 50 bullets, from a course starting bullet to a final burnishing bullet. 10 each of them. You're supposed to use a minimal load. They was as little deformation of the bullet as possible in order to knock down high spots. I used the lowest book load for IMR4350 I could find for a 250 grain bullet since they provide what looked like Sierra Matchkings in the kit. I loaded them up and shot the first ten. True to form the first 3-4 were all over. Then shots 5 on started coming together.

I didn't take a picture of the rest but they all clustered right in there. After the first 10 I cleaned it and noticed it felt smoother and it cleaned up much faster.

These are actually 3-5 from treatment #2. Again I didn't take a picture of all 10 but it was promising. Cleaned again, smoother and easier.

This one they are all staying relatively close. At least better.

Now we are talking. I actually started getting excited. This is the best the rifle has even done from a bare steel barrel.

That's the last 10 and there is the tiniest copper streaking. Right now I've got the barrel soaking with copper killer and once it's clean I'll DBC it again. I'm thinking I've got it about as good as I can get it.

So, if you have a rough barrel you don't wanna get rid of, give them a try. They aren't expensive and if you have the time they seem to help.