So the story goes I bought a LOAD of 6.5-300 WBY Mag brass about half of it unfired, the other half fired. The new brass chambered as it should, the once fired brass (from someone else's rifle) would not. It had the bulge above the rim. I also have a .257 WBY mag that the brass is starting the bulge after 6 reloads, nothing else wrong with the brass, it has plenty of life minus the bulge.

I started doing my research thinking surely someone had already addressed this problem. I found someone had! Innovative Technologies sells a special collet die for $139.99 OK I thought I would just order one. The first issue is they say they have a 3 to 6 month backorder wait. The second issue is they use PAYPAL as their online credit card merchant. I believe PAYPAL hates gun owners and is 100% ANTI GUN. I REFUSE to ever deal with them, EVER. RANT OVER

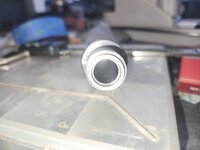

After work this evening I went in the hobby machine shop and made my own. I used 17-4ph stainless, it took less than an hour to make. It works PERFECTLY! I fixed all my brass 6.5-300 and .257 it all chambers perfectly now. My design does not use a collet, simpler in design but effective.

Below are some pics of what I made.

This die ONLY sizes the base in front of the belt, where the problem always is.

I started doing my research thinking surely someone had already addressed this problem. I found someone had! Innovative Technologies sells a special collet die for $139.99 OK I thought I would just order one. The first issue is they say they have a 3 to 6 month backorder wait. The second issue is they use PAYPAL as their online credit card merchant. I believe PAYPAL hates gun owners and is 100% ANTI GUN. I REFUSE to ever deal with them, EVER. RANT OVER

After work this evening I went in the hobby machine shop and made my own. I used 17-4ph stainless, it took less than an hour to make. It works PERFECTLY! I fixed all my brass 6.5-300 and .257 it all chambers perfectly now. My design does not use a collet, simpler in design but effective.

Below are some pics of what I made.

This die ONLY sizes the base in front of the belt, where the problem always is.

Attachments

Last edited: