My dilemma with the LCD

Over the years adjusting the LCD has been fruitless, until recently. I read from another forum what to do about it.

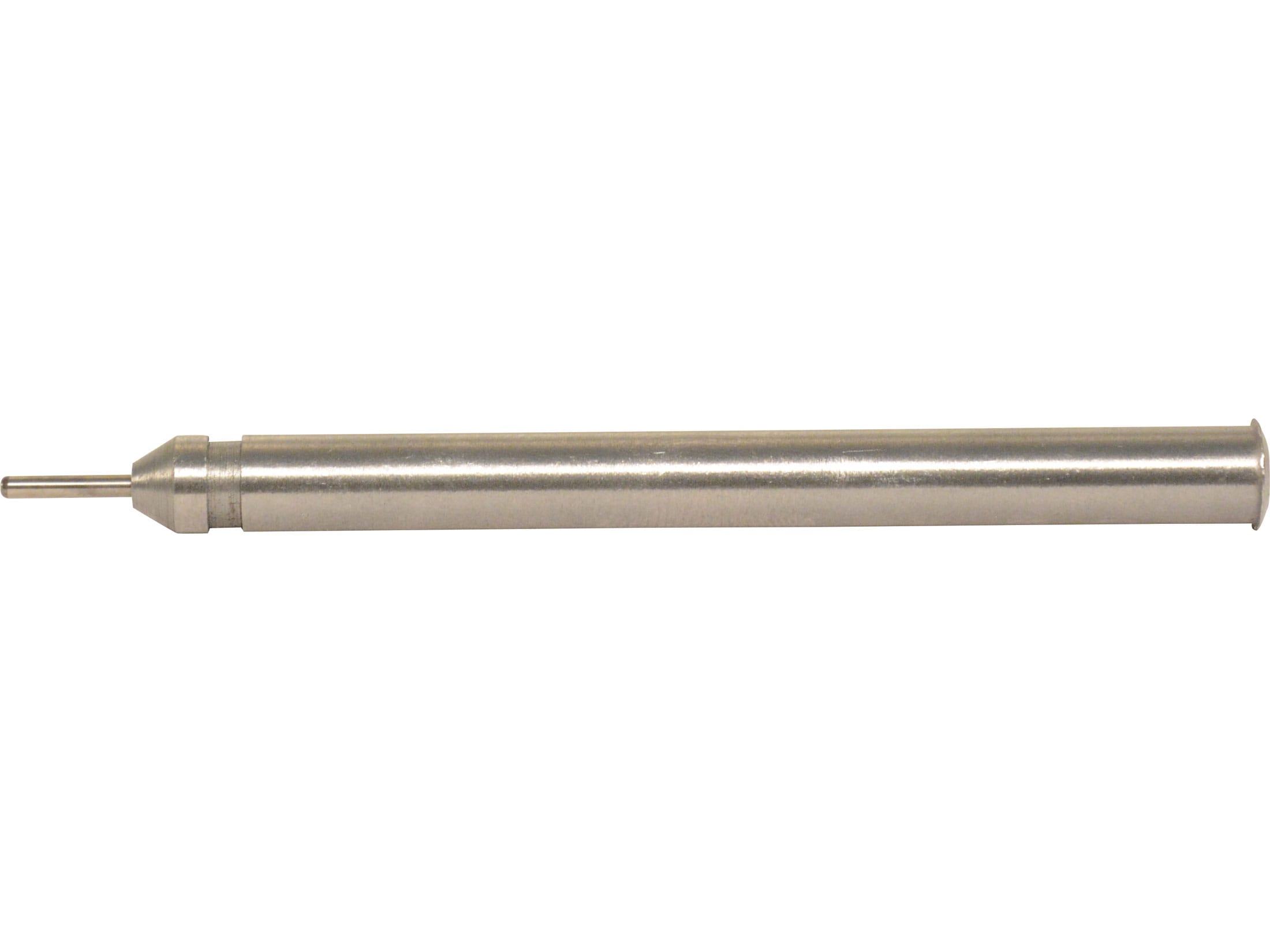

Place a washer over the case on the sell holder to prevent the mandrel from making contact with the base of the case preventing the collet from closing enough on the case neck. Another guy off another forum said just put a spacer under the cap of the die. But that wouldn't work, so I thought about it and put a small washer between the mandrel, under the small lip of the mandrel and the collet sleeve. Works great. I contacted Lee and they are sending me out a new mandrel after telling them about the lip on top of the mandrel isn't thick enough to prevent the mandrel from staying away from the case head that prevents the collet to close enough, sizing enough. So all you guys who've been struggling or hung up the LCD, there is hope. For all you fraternity guys with your high end gear, disregard !

Over the years adjusting the LCD has been fruitless, until recently. I read from another forum what to do about it.

Place a washer over the case on the sell holder to prevent the mandrel from making contact with the base of the case preventing the collet from closing enough on the case neck. Another guy off another forum said just put a spacer under the cap of the die. But that wouldn't work, so I thought about it and put a small washer between the mandrel, under the small lip of the mandrel and the collet sleeve. Works great. I contacted Lee and they are sending me out a new mandrel after telling them about the lip on top of the mandrel isn't thick enough to prevent the mandrel from staying away from the case head that prevents the collet to close enough, sizing enough. So all you guys who've been struggling or hung up the LCD, there is hope. For all you fraternity guys with your high end gear, disregard !