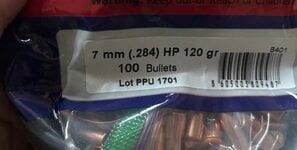

I have a t/c contender carbine barrel in 7mm tcu. I’ve not gotten it to shoot well. Finally have headspace and ogive comparators and the 7mm bullets I bought are ppu. When I started checking loaded rounds I found the only real differences to be base to give but oal was in .001 to .003 thousandths but to ogive over .014” difference. Since I haven’t run into random flyer problems before on a consistent basis is .012 to .014” enough to cause wild flyers. I know different bullets at the same weight will impact different area is that big enough difference to be considered a different style bullet? I’m measuring the remaining bullets and keeping anything within a .002” range to load.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: this_feature_currently_requires_accessing_site_using_safari

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Ogive length impact

- Thread starter sphingta

- Start date

RL338

Handloader

- Mar 23, 2017

- 3,741

- 6,373

What bullets is giving you such variance in base to ogive? 0.014” is a sizable difference when your COAL only varies by 0.001-0.003”.When I started checking loaded rounds I found the only real differences to be base to give but oal was in .001 to .003 thousandths but to ogive over .014” difference.

- Thread starter

- #3

RL338

Handloader

- Mar 23, 2017

- 3,741

- 6,373

With that amount of variance with the ogive measurement. Is there a diameter difference in those 2 bullet?

- Thread starter

- #5

No that’s the base of the bullets to ogive. The diameter is the same as is the bullet length within reason just a difference to the ogive which seems like it would make it fly much different. I have been loading for a long time but this gun has kicked my butt. Usually when it’s the gun the bullets will land anywhere. I can shoot 2 or 3 rounds within an inch or two hell, 3” would be fine, which is all I want for 100 yards with that gun but then one goes out 6-12”. If I want to do short range hunting and can’t hit a heart lung shot reliably it does me know good. I haven’t run across “bad bullets” like this. I’m still not sure it’s them but I have never measured ogive consistentcy so I have no idea if this could be a problem. Logically it seems like it would but no data to back it up.

Last edited:

- Thread starter

- #6

Just bought some 150 ballistic tips gonna measure them and load some of those up. It’s the only 7mm I had and bought the bullets during Covid since that was what was available but I’ll try the new bullets but still want to know from someone whose been using comparators if that was normal or if that would cause random huge flyers.

- Thread starter

- #7

300WSM

Handloader

- Dec 24, 2011

- 1,197

- 803

You have something else wrong.

That's my feeling from your description.

100 yards is not that far. To have a flyer that far off ...@ 100 yards...

It's more than those bullets.

I had a nearly identical situation with a rifle.

3 shot group...2 very close, 1 several inches out.

I chased my tail on that for a while.

Telling myself "maybe it's this ____"

"Maybe it's that_____"

After many experiments....

I put the bore sighter on the scope...

Took note.

Pulled bore sighter out and bumped scope with my palm several times.

Checked it again.

Whoa...that s.o.b. moved.

Repeated...

Yep....the damn thing is moving.

I was so convinced it couldn't be the equipment when in fact it was the equipment afterall

That's my feeling from your description.

100 yards is not that far. To have a flyer that far off ...@ 100 yards...

It's more than those bullets.

I had a nearly identical situation with a rifle.

3 shot group...2 very close, 1 several inches out.

I chased my tail on that for a while.

Telling myself "maybe it's this ____"

"Maybe it's that_____"

After many experiments....

I put the bore sighter on the scope...

Took note.

Pulled bore sighter out and bumped scope with my palm several times.

Checked it again.

Whoa...that s.o.b. moved.

Repeated...

Yep....the damn thing is moving.

I was so convinced it couldn't be the equipment when in fact it was the equipment afterall

300WSM

Handloader

- Dec 24, 2011

- 1,197

- 803

Something else I want to tell you...This is the average to low. The largest was .511View attachment 24813View attachment 24815

That comparator tool is great...however...

It's very easy to get erratic readings if it's not set up right and if your bullet is the slightest bit cocked in there.

I'm not questioning your caliper measuring prowess but just thinking of all possibke things you could be experiencing

- Thread starter

- #10

Yea moved, spun, seated to get lowest reading. Been there done that. But not saying it not possible. Got about 20% longer or shorter than .504 to .506. Checked my 6.5 creedmoor I had loaded that shot .3 to .7 inches at 100 in 3 different guns that had no more than .002” Difference to ogive but that doesn’t mean crap to me because it’s still only the second set of data I have. They just seem to shoot good. Any way I’ m not giving up just wanted to know if something like that Could cause the problem.

flyingagg

Handloader

- Dec 16, 2019

- 510

- 543

There is CBTO and COAL. When there is inconsistency in the bullets, it can affect how deep the bulled is set in case, changing pressures. I can also affect jump. I can go intoYea moved, spun, seated to get lowest reading. Been there done that. But not saying it not possible. Got about 20% longer or shorter than .504 to .506. Checked my 6.5 creedmoor I had loaded that shot .3 to .7 inches at 100 in 3 different guns that had no more than .002” Difference to ogive but that doesn’t mean crap to me because it’s still only the second set of data I have. They just seem to shoot good. Any way I’ m not giving up just wanted to know if something like that Could cause the problem.

More details when I am back at home in a couple of days

300WSM

Handloader

- Dec 24, 2011

- 1,197

- 803

Yeah the norm I've found is .001-.003 maybe with an occasional. 004-.005 in there but not often.Yea moved, spun, seated to get lowest reading. Been there done that. But not saying it not possible. Got about 20% longer or shorter than .504 to .506. Checked my 6.5 creedmoor I had loaded that shot .3 to .7 inches at 100 in 3 different guns that had no more than .002” Difference to ogive but that doesn’t mean crap to me because it’s still only the second set of data I have. They just seem to shoot good. Any way I’ m not giving up just wanted to know if something like that Could cause the problem.

Mostly .001-.003 tolerance.

That said there is an easy way to check all this out.

Load up 6 of your closest ogive measured bullets (if they exist)and go shoot them.

If still getting a wild flyer something else is wrong.

That would be a quick way to know eliminate equipment and or prove your theory possible....

No?

RL338

Handloader

- Mar 23, 2017

- 3,741

- 6,373

With open tip bullets you are getting 0.001-0.003” difference in base to tip on a loaded round that is a good start. However with a base to ogive of that same loaded round has a variable of 0.014” makes wonder how or where your seating stem is contacting the bullet.

As to throwing a 1 shot 6-12” out of 3 , I would start with the norm. Screws tight , crown of barrel condition , and try a reliable scope.

As to throwing a 1 shot 6-12” out of 3 , I would start with the norm. Screws tight , crown of barrel condition , and try a reliable scope.

- Thread starter

- #14

Yes tomorrow I will load some up. Not to worried about the actual load and velocity but about the ogive length. Like was stated with Tom .001-.003” is acceptable to me for oal. I’ll shoot them and if it’s a group I can go from there. If not I will probably redo the crown as I’ve tried a lot of other stuff. I will also recheck the scope mount. Pretty sure I’ve already done that but it can’t hurt. I’ll do both the 120 ppu and 150 ballistic tips. Probably 10 rounds a piece.

300WSM

Handloader

- Dec 24, 2011

- 1,197

- 803

You said everything but possibly the biggest culprit.Yes tomorrow I will load some up. Not to worried about the actual load and velocity but about the ogive length. Like was stated with Tom .001-.003” is acceptable to me for oal. I’ll shoot them and if it’s a group I can go from there. If not I will probably redo the crown as I’ve tried a lot of other stuff. I will also recheck the scope mount. Pretty sure I’ve already done that but it can’t hurt. I’ll do both the 120 ppu and 150 ballistic tips. Probably 1⁵0 rounds a piece.

The actual scope.

Trust me...I was there before.

Chasing a flyer for a year or more and checked everything. Reinventing the wheel.

I just couldn't/wouldn't acknowledge that possibly the scope is messed up.

It has to be everything but that.

Ultimately, finding out the teticke would move just enough to throw a flyer.

Sphingta,

The shape of the ogive can vary from bullet to bullet. I think it depends on the tooling used for that production run (lot). Usually, the BTO measurements for the jam length in a rifle for the bullets in a box or a lot will be relatively consistent. However, the readings from lot to lot can be different. I check the BTO jam length for each lot of bullets I use. Them I adjust my seating depth to maintain the bullet jump that I want. This also helps to compensate for any wear on the lands of the rifling as the rifle is shot more.

When using seconds, in which bullets could be from more than one lot, I have seen more variation in a package.

I just started loading for a 6.5 Creedmoor with 120 gr. Nosler BT's. I am finding Base-to-Ogive readings for the jam length in this rifle to vary by as much as 0.050". Yes, 50 thousand's of an inch. That amount of variation can cause a flyer.

I have tried to measure differences in diameter of these bullets but not really seeing much difference.

When I inspect the bore of the rifle I can see that the free-bore area seems to be tight and somewhat tapered. I can see remnants of the lands all the way to neck of the chamber. I use the Hornady bullet comparator gauge. When I slide a bullet into the bore, I can feel the difference from bullet to bullet. Some will just slide in freely and then stop. Those have the shortest BTO measure. Others will slide in and then I can fell a slight resistance for a ways until it stops. Those bullets have a longer BTO measurement. I think I am feeling the slightest variation in ogive shape and diameter. Variations as small as 0.0001" to 0.0002".

For the time being, I am measuring each bullet and separating them according to BTO measurements for jam length in the rifle. Then I load a test with all bullets of similar BTO measurements.

I think that the lands will wear a little with some firings and then I will get more consistent results.

Hornady factory 140 gr. match loads jam into the rifling and the rifling leaves long marks on the bullets when extracted.

The shape of the ogive can vary from bullet to bullet. I think it depends on the tooling used for that production run (lot). Usually, the BTO measurements for the jam length in a rifle for the bullets in a box or a lot will be relatively consistent. However, the readings from lot to lot can be different. I check the BTO jam length for each lot of bullets I use. Them I adjust my seating depth to maintain the bullet jump that I want. This also helps to compensate for any wear on the lands of the rifling as the rifle is shot more.

When using seconds, in which bullets could be from more than one lot, I have seen more variation in a package.

I just started loading for a 6.5 Creedmoor with 120 gr. Nosler BT's. I am finding Base-to-Ogive readings for the jam length in this rifle to vary by as much as 0.050". Yes, 50 thousand's of an inch. That amount of variation can cause a flyer.

I have tried to measure differences in diameter of these bullets but not really seeing much difference.

When I inspect the bore of the rifle I can see that the free-bore area seems to be tight and somewhat tapered. I can see remnants of the lands all the way to neck of the chamber. I use the Hornady bullet comparator gauge. When I slide a bullet into the bore, I can feel the difference from bullet to bullet. Some will just slide in freely and then stop. Those have the shortest BTO measure. Others will slide in and then I can fell a slight resistance for a ways until it stops. Those bullets have a longer BTO measurement. I think I am feeling the slightest variation in ogive shape and diameter. Variations as small as 0.0001" to 0.0002".

For the time being, I am measuring each bullet and separating them according to BTO measurements for jam length in the rifle. Then I load a test with all bullets of similar BTO measurements.

I think that the lands will wear a little with some firings and then I will get more consistent results.

Hornady factory 140 gr. match loads jam into the rifling and the rifling leaves long marks on the bullets when extracted.