truck driver

Ammo Smith

- Mar 11, 2013

- 7,496

- 1,299

Besides being a member here I'm also on the Cast Boolit forum.

There is a trend going on that is fairly new to me but has been around for a while and that is powder coating Lead bullets to cut down on leading and helping to keep the lead level down in your body from shooting and handling lead bullets.

The process involves dry or wet coating the lead bullet with poly coat paint instead of the usual alox grease when sizing.

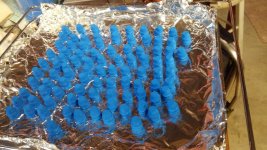

I'm trying the shake and bake dry method to apply the poly coat to the bullets I cast.

I haven't perfected the method yet and my bullets don't look great but if it reduces the leading as most claim I think it is worth effort since I go through thousands of lead bullets each year with most of them hand cast by me.

With the polymer coating you can shoot lead bullets in AR style rifles and Glock pistols with out clogging the gas system on the rifle or leading the polygonal rifling on a Glock pistol.

This was done using Harbor Freight poly coat paint and baked in a Toaster oven/Air fryer.

With Harbor Freight powder coat paint you either have to spray it on or coat the bullets twice.

The picture is of once coated .45 cal 185gr target bullets that I cast.

Two coats will make them look better but not shoot any better.

There is a trend going on that is fairly new to me but has been around for a while and that is powder coating Lead bullets to cut down on leading and helping to keep the lead level down in your body from shooting and handling lead bullets.

The process involves dry or wet coating the lead bullet with poly coat paint instead of the usual alox grease when sizing.

I'm trying the shake and bake dry method to apply the poly coat to the bullets I cast.

I haven't perfected the method yet and my bullets don't look great but if it reduces the leading as most claim I think it is worth effort since I go through thousands of lead bullets each year with most of them hand cast by me.

With the polymer coating you can shoot lead bullets in AR style rifles and Glock pistols with out clogging the gas system on the rifle or leading the polygonal rifling on a Glock pistol.

This was done using Harbor Freight poly coat paint and baked in a Toaster oven/Air fryer.

With Harbor Freight powder coat paint you either have to spray it on or coat the bullets twice.

The picture is of once coated .45 cal 185gr target bullets that I cast.

Two coats will make them look better but not shoot any better.