Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: this_feature_currently_requires_accessing_site_using_safari

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

180 grain AccuBond in the 300 Weatherby

- Thread starter slickrem

- Start date

hunter24605

Handloader

- Apr 30, 2016

- 2,452

- 3,888

I've usually found them pretty much interchangeable. There may be a very slight shift in POI, but they tend to group almost the same.

- Nov 4, 2004

- 24,625

- 7,241

I get excellent accuracy with the BT, AB and ABLR.

It's going to depend on your rifle and load.

JD338

It's going to depend on your rifle and load.

JD338

TackDriver284

Handloader

- Feb 13, 2016

- 2,369

- 1,694

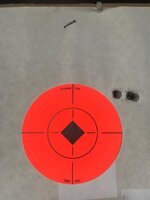

Accubonds are as accurate as the Ballistic Tips in my 300 Win Mag, both have the same POI at 300 yards with RL22.

Both pics with the AccuBond / RL 22 @ 300 yards, when I tested them a couple years back.

Both pics with the AccuBond / RL 22 @ 300 yards, when I tested them a couple years back.

Attachments

D21ALASKA

Handloader

- Oct 29, 2013

- 274

- 269

Depends on the rifle. My '06 shoots the 165's of each the same. Same charge/velocity/groups/POI. My .308 with 150's not so much. Completely different.

- Thread starter

- #6

- Nov 4, 2004

- 24,625

- 7,241

The cannelure should not make a difference.

JD338

JD338

- Oct 30, 2004

- 24,148

- 2,770

Same in my guns

- Thread starter

- #9

I'm gonna hijack my own thread.

Can aged brass, even after annealed, not move much with a max load and bullets touching lands ? This is LC 69 .30-06 brass. Also virgin Winchester .270 Winchester brass. I didn't anneal the .270 brass. Who knows how long the virgin brass has been around, before I got it.

Can aged brass, even after annealed, not move much with a max load and bullets touching lands ? This is LC 69 .30-06 brass. Also virgin Winchester .270 Winchester brass. I didn't anneal the .270 brass. Who knows how long the virgin brass has been around, before I got it.

TackDriver284

Handloader

- Feb 13, 2016

- 2,369

- 1,694

If its aged, anneal it first and load away.

Old or new brass won't move much if the chamber is tight.I'm gonna hijack my own thread.

Can aged brass, even after annealed, not move much with a max load and bullets touching lands ? This is LC 69 .30-06 brass. Also virgin Winchester .270 Winchester brass. I didn't anneal the .270 brass. Who knows how long the virgin brass has been around, before I got it.

- Thread starter

- #12

Are newer factory rifles come with tighter chambers ? 2.048 max HS and 2.058 minimum is SAMMI. I get 2.042 after a few attempts. The brass chambers fine, so I'm thinking the chamber is clean. Naturally the blow by on the necks might be fouling the shoulder area ?Old or new brass won't move much if the chamber is tight.

I just checked the shoulder in the chamber.. It's shiny. Good to go I suppose.

Last edited:

TackDriver284

Handloader

- Feb 13, 2016

- 2,369

- 1,694

And that minimizes carbon rings also.No idea on new rifles. I stopped trimming my cases to the trim to length. I trim to max length to cut down on the blow by. The outside of my necks have less carbon on them since i started doing it.

- Thread starter

- #15

I'm aware of carbon rings and just dealt with it. I just scrubbed it out recently. If it's there, that would prevent brass from growing. Sound right ?And that minimizes carbon rings also.

- Thread starter

- #16

I had a stiff bolt extracting, but it chambered with moderate resistance. Not bad.No idea on new rifles. I stopped trimming my cases to the trim to length. I trim to max length to cut down on the blow by. The outside of my necks have less carbon on them since i started doing it.

Like Sako 2 said about a tight chamber.

I did anneal it, but it won't budge past a few though from FL sized.If its aged, anneal it first and load away.

TackDriver284

Handloader

- Feb 13, 2016

- 2,369

- 1,694

No it wont prevent brass from growing, but it may pinch the case mouth if you have a thick carbon ring. The carbon ring gets thick and hard enough to squeeze the end of the case mouths and in turn grips the bullet tighter when chambering and possibly contact the bullet as well (if really bad) and cause pressure spikes. It can cause hard bolt closure/ bullets sticking in the freebore on extraction if neck tension is low enough.I'm aware of carbon rings and just dealt with it. I just scrubbed it out recently. If it's there, that would prevent brass from growing. Sound right ?

You need to know the exact measurement of your chamber and neck length so you can trim your brass longer to prevent this issue. I had forgotten about this when I trimmed off .010" off my 300 Win Mag brass, but I don't have a carbon ring, I keep it pretty much clean. Next time, I'll let it grow and check with a bore scope on how much gap there is between the end of the case mouth and the chamber neck stop when closing the bolt. I can do this from the muzzle end. I use a straw as a sleeve and insert the straw in the muzzle and run the borescope in.

Last edited:

- Thread starter

- #18

I use a split neck case gauge made from a case. No carbon ring.No it wont prevent brass from growing, but it may pinch the case mouth if you have a thick carbon ring. The carbon ring gets thick and hard enough to squeeze the end of the case mouths and in turn grips the bullet tighter when chambering and possibly contact the bullet as well (if really bad) and cause pressure spikes. It can cause hard bolt closure/ bullets sticking in the freebore on extraction if neck tension is low enough.

You need to know the exact measurement of your chamber and neck length so you can trim your brass longer to prevent this issue. I had forgotten about this when I trimmed off .010" off my 300 Win Mag brass, but I don't have a carbon ring, I keep it pretty much clean. Next time, I'll let it grow and check with a bore scope on how much gap there is between the end of the case and the chamber neck stop when closing the bolt. I can do this from the muzzle end. I use a straw as a sleeve and insert the straw in the muzzle and run the borescope in.

Attachments

hunter24605

Handloader

- Apr 30, 2016

- 2,452

- 3,888

Ideally, to eliminate any guessing on your chamber, a cerrosafe cast is cheap and simple, that will give you an exact copy of your chamber.

- Thread starter

- #20

yeah I know..... I'll get one. ThanksIdeally, to eliminate any guessing on your chamber, a cerrosafe cast is cheap and simple, that will give you an exact copy of your chamber.