Greetings,

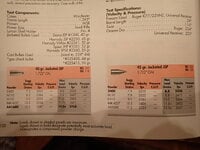

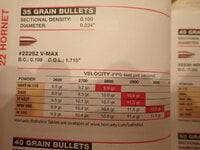

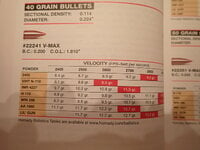

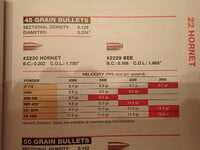

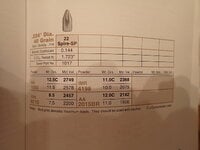

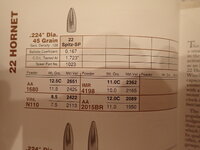

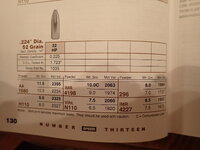

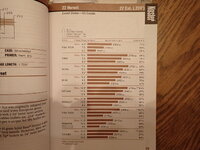

After a long and drawn out ordeal with Savage, I finally fixed my Model 25 myself and am back on the reloading bench looking for that perfect coyote load. My Nosler book lists 13g of Lil'Gun for the 40g bullet. When I went to the on Nosler on line reloading data site, that load is now a maximum of 11g for the same bullet and powder combination. Did the bullet get redesigned? Is my manual wrong? Is the on line data wrong? Anyone have an insight into why that huge difference is there? 2 grains is huge in that little case.

Thanks for reading.

After a long and drawn out ordeal with Savage, I finally fixed my Model 25 myself and am back on the reloading bench looking for that perfect coyote load. My Nosler book lists 13g of Lil'Gun for the 40g bullet. When I went to the on Nosler on line reloading data site, that load is now a maximum of 11g for the same bullet and powder combination. Did the bullet get redesigned? Is my manual wrong? Is the on line data wrong? Anyone have an insight into why that huge difference is there? 2 grains is huge in that little case.

Thanks for reading.

Attachments

Last edited: