- Thread starter

- #21

nvbroncrider

Handloader

- Aug 20, 2011

- 3,085

- 4

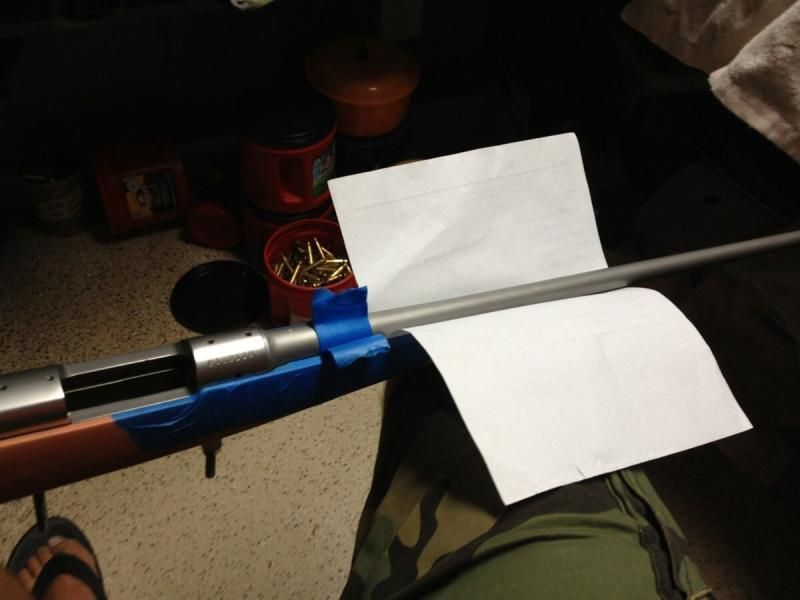

Thanks guys well when I get the kit it will get bedded with lots of pictures.

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: this_feature_currently_requires_accessing_site_using_safari

Remove everything as already noted.nvbroncrider":2bg2fuus said:So what your saying is cover the whole stock and action in release agent if you don't want anything there and then cover it again.