nosler06

Handloader

- Nov 13, 2012

- 278

- 81

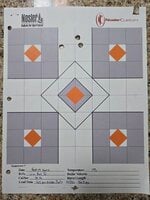

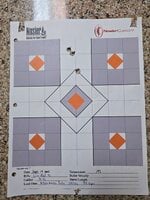

I have an older 30-06 Winchester Model 70 and am thinking of a switch to 165grn Nosler Partitions from my usual 180grn Parts. I'm using H4350 powder and CCI primers. This is today's test run. I'm looking at the 55.5grn or the 56.5grn. I think I might be able to tweak a bit around the 56.5grn loads to keep the velocity higher. What do you all think?