Desert Fox

Handloader

- Aug 14, 2006

- 1,965

- 3

Just finished weight sorting the newly loaded 6 BR rounds that I'm testing this weekend. It is always my contention that uniformity and accuracy of the load goes hand in hand. Or put it another way, you cannot have accuracy without uniformity.

So here's the result I've got after weighing 50 rounds of fully prepped 6BR cases loaded with 30 grains of Hodgdon Varget, Remington 7.5 primers and 105 grain Hornady A-Maxes. By the way I used Lyman DPS 1200 to dispensed the powder and verified for consistency using my RCBS 1010 balance scale. Anything over 30.0 from Lyman is discarded. Amazing how this two scales compliment each other.

1 - 264.6

2 - 264.7

4 - 264.8

2 - 264.9

4 - 265.0

3 - 265.1

6 - 265.2

7 - 265.3

8 - 265.4

3 - 265.5

6 - 265.6

2 - 265.8

1 - 265.9

1 - 266.3

If I exclude the two oddball (266.3 and 264.6), the loaded round falls within 1.2 grain apart. I have 31 loaded round that falls within half grain (265.0 - 265.5). I will shoot those round first and then shoot the rest later and compare the result. I want to see if there is a discernible difference in velocity from half grain to 1.2 grain. If there is , then this little 6BR will show it.

Went to the range this morning and here's my unscientific result. The samples were so small that statistically, the result is inconclusive. However, it somewhat supported my contention that uniformity of the load is very important if you want a predictable and consistent result. At short distance, the difference is probably insignificant and won't matter much, but at long range, it can have a huge impact on your group.

Since I was shooting a coated bullet, I did not start recording the velocity of the round until I saw that speed had stabilized. I shot a total of 6 coated rounds and then waited until the barrels cools off and began recording.

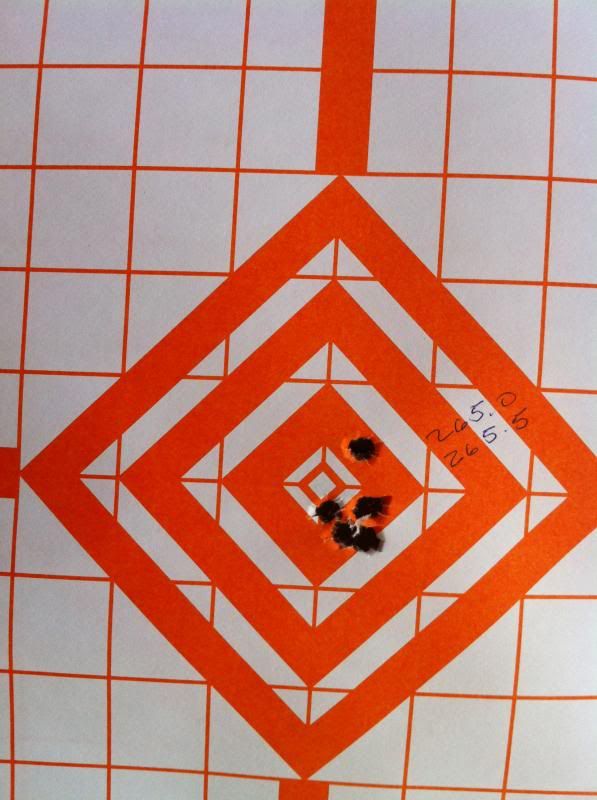

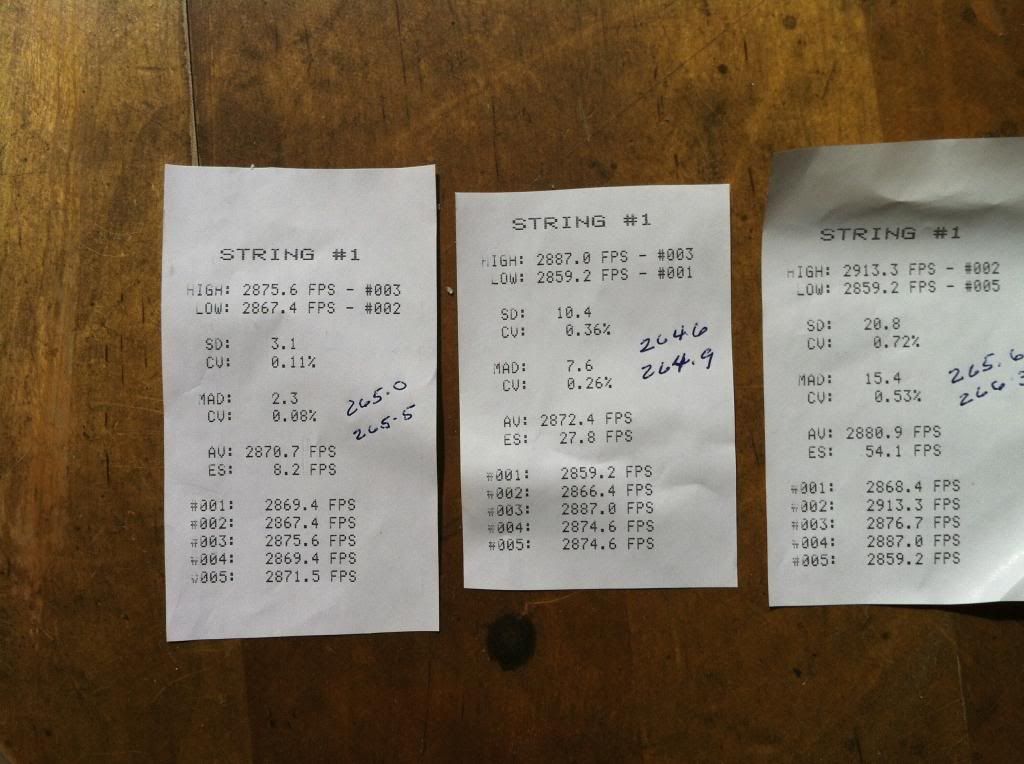

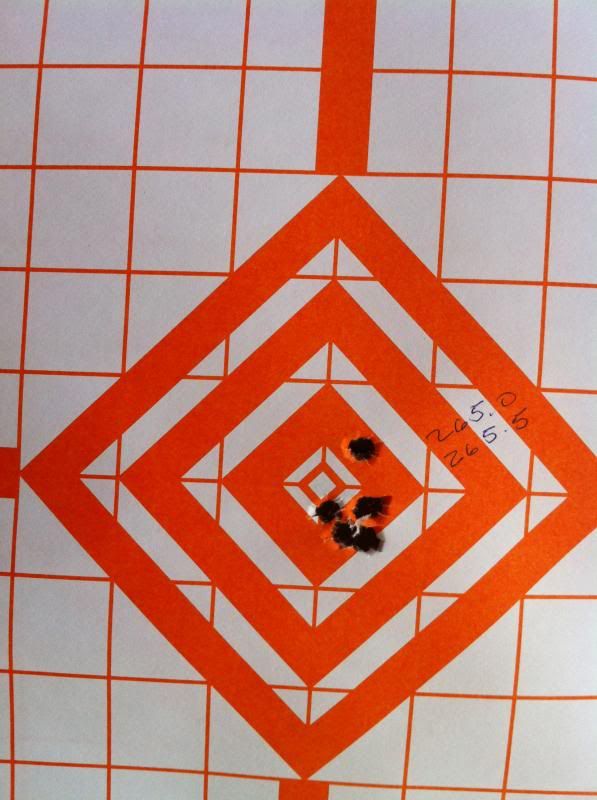

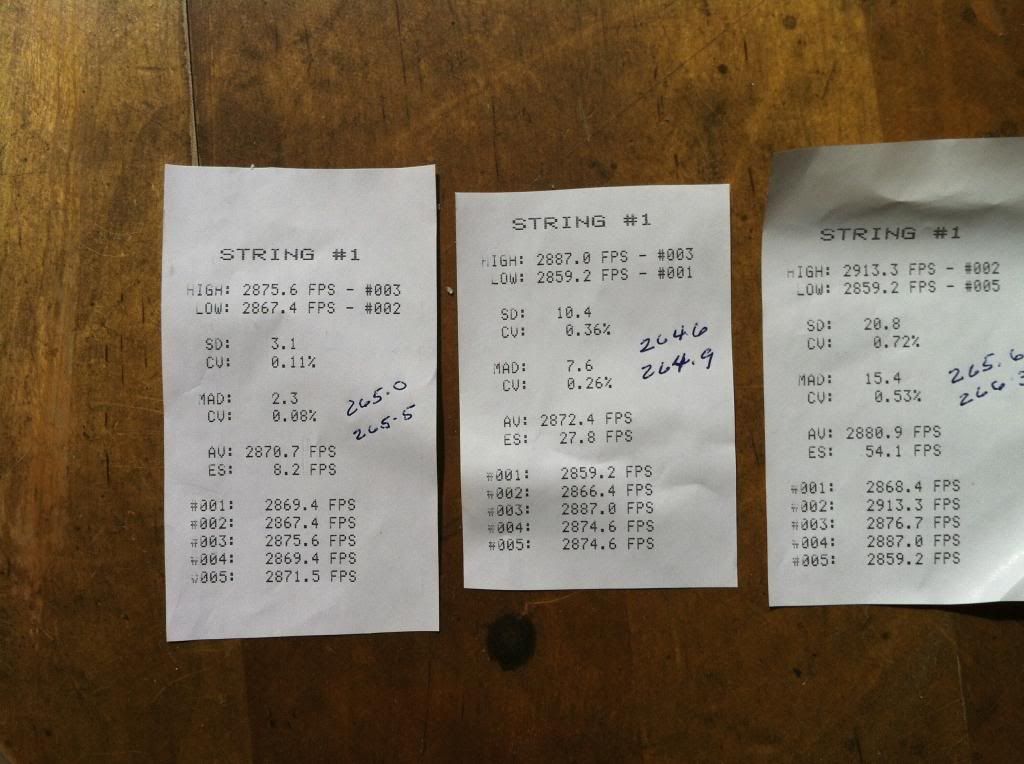

The 5 shot group on the left was shot with rounds weighing between 265.0 to 265.5. The 5 shot group in the middle was shot with rounds weighing 264.6 to 264.9 and the 5 shot group on the right was with rounds weighing 265.6 to 266.3. I pick up rounds in random from each group with no weight order in particular.

As you can see, the 265,0 - 265.5 grain load has single digit ES and SD. I have 31 of these out of 50 pieces of brass that I've loaded. The 264.6 - 264.9 grain load has low double digit SD and ES and I only have 9 of those round out of 50. The 259.6 - to 266.3 grain load has a higher double digit SD and ES. I have 10 of those round out of 50. This group also recorded the highest velocity. That make perfect sense since these were the heaviest of all loaded round. If I have to cull the load that I'm going to use for competition, the 265.0 - 265.5 will be the obvious choice. It also helps that majority of the loaded round falls within these weight group too.

Here's the 5 shot group from that group. The flyer was my fault.

So here's the result I've got after weighing 50 rounds of fully prepped 6BR cases loaded with 30 grains of Hodgdon Varget, Remington 7.5 primers and 105 grain Hornady A-Maxes. By the way I used Lyman DPS 1200 to dispensed the powder and verified for consistency using my RCBS 1010 balance scale. Anything over 30.0 from Lyman is discarded. Amazing how this two scales compliment each other.

1 - 264.6

2 - 264.7

4 - 264.8

2 - 264.9

4 - 265.0

3 - 265.1

6 - 265.2

7 - 265.3

8 - 265.4

3 - 265.5

6 - 265.6

2 - 265.8

1 - 265.9

1 - 266.3

If I exclude the two oddball (266.3 and 264.6), the loaded round falls within 1.2 grain apart. I have 31 loaded round that falls within half grain (265.0 - 265.5). I will shoot those round first and then shoot the rest later and compare the result. I want to see if there is a discernible difference in velocity from half grain to 1.2 grain. If there is , then this little 6BR will show it.

Went to the range this morning and here's my unscientific result. The samples were so small that statistically, the result is inconclusive. However, it somewhat supported my contention that uniformity of the load is very important if you want a predictable and consistent result. At short distance, the difference is probably insignificant and won't matter much, but at long range, it can have a huge impact on your group.

Since I was shooting a coated bullet, I did not start recording the velocity of the round until I saw that speed had stabilized. I shot a total of 6 coated rounds and then waited until the barrels cools off and began recording.

The 5 shot group on the left was shot with rounds weighing between 265.0 to 265.5. The 5 shot group in the middle was shot with rounds weighing 264.6 to 264.9 and the 5 shot group on the right was with rounds weighing 265.6 to 266.3. I pick up rounds in random from each group with no weight order in particular.

As you can see, the 265,0 - 265.5 grain load has single digit ES and SD. I have 31 of these out of 50 pieces of brass that I've loaded. The 264.6 - 264.9 grain load has low double digit SD and ES and I only have 9 of those round out of 50. The 259.6 - to 266.3 grain load has a higher double digit SD and ES. I have 10 of those round out of 50. This group also recorded the highest velocity. That make perfect sense since these were the heaviest of all loaded round. If I have to cull the load that I'm going to use for competition, the 265.0 - 265.5 will be the obvious choice. It also helps that majority of the loaded round falls within these weight group too.

Here's the 5 shot group from that group. The flyer was my fault.