nvbroncrider

Handloader

- Aug 20, 2011

- 3,085

- 4

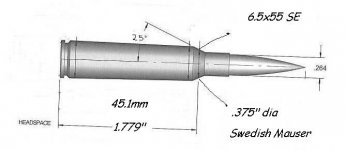

Okay guys I'm stumped and totally confused. On my 6.5X55 I had made up some rounds last year to do some testing with some 125PT I have been using Nosler brass once fired neck sized some chamber nice and smooth others very stiff. All rounds were loaded shorter than the lands after an accuracy test nothing popped out. I fired the last that would chamber this week. So tonight I went through the whole lot of brass and tried chambering each piece of brass most wouldn't chamber and some would with quite a bit of force. Borderline beat the bolt shut. So I got out a new box of brass and chambered one smooth as silk. So I set up my FL die and adjusted it per the manual and tried it in the rifle no joy I continued cranking down on my die until it chambered like the factory new unfired brass. I had two unfired rounds left that wouldn't chamber they were COAL of 3.025" if I recall correctly which was the Nosler #7 recommended seating depth. So I pulled the bullets and powder figured I'd try to fire the primers they chambered and fired. So now I'm totally confused. Overall length of the brass is well under SAMMI max. I took a ton of measurements before sizing and there is only one thing I noted that raised flags as to why I couldn't chamber smoothly. At the shoulder SAMMI max diameter is .435" I consistently was measuring .440-.442" on the brass before sizing, each round that I could chamber a shiny ring was appearing at the body shoulder junction, factory new brass is .436". At the case head SAMMI is .480" factory and fired rounds were .477-.478" as was factory new. Now looking at the drawings this case as a fair amount of taper over the length of the cartridge .045" from the case head to the shoulder. My big question is why did the last two rounds that I pulled chamber without an issue but was shooting 3.100" fine on factory new brass but these at 3.025" wouldn't chamber with a bullet but chambered fine with no bullet? I'm totally confused and have my ears open looking for answers or suggestions.