TackDriver284

Handloader

- Feb 13, 2016

- 2,957

- 3,202

I may need some advice, but can think what the issue may be. " Case Volume" but not sure, hope you guys can advise.

Nosler book minimum 74 and max is 78 grains

Lapua brass ( current ) H20 is 92.29 gr and Norma brass is 95.20 ( recently used ) / started using Lapua last year and been using Norma and never had high speed or pressure issues if following Nosler manual powder recommendations

300 Win Mag using H1000, CCI 250, 200 grain Accubonds, COAL 3.515" Lapua brass, 3 round groups in .4 increments:

Fouler : 76.6 grains / 3,005 fps

77.0 grains / 3041, 3075, 3068 fps

77.4 grains / 3052, 3018, 3061 fps

77.8 grains / 3096, 3025, stopped shooting

78.2 grains N/A

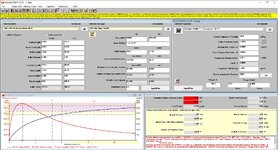

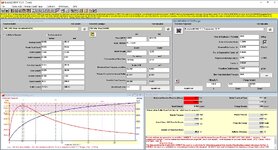

Speed is incredibly fast with the slow H1000 powder, ES is all over the map and I measured to the kernel using the FX-120i and expected 2900-2950 fps and grouping was not good, best is 1.25" to 1.5" @ 100. Max is 78 grains and speed should be around 2851 fps as shown in the manual and I was pushing 3,043 fps with 77.4 grains. Here is a couple of charts from QL to see what pressure I'm at. First pic is QL tweaked to use 77.4 grains with the Lapua H20 volume. The Norma brass that I used to use has a larger case volume, unlike the current Lapua brass which is 92.29 compared to 95.20. Would the case volume be the issue why its pushing too fast?

OAL is .010" off the lands, but if seating deeper, then pressure will rise as well

I may want to retry H1000 with lower charges from 74 to 76 grains which is low to mid recommendations in the Nosler manual and seat the bullets deeper to .050" off the lands since my COAL is 3.515" and the manual says max 3.340" or dump the H1000 and go back to RL 22 or RL 25 and do a ladder?

Nosler book minimum 74 and max is 78 grains

Lapua brass ( current ) H20 is 92.29 gr and Norma brass is 95.20 ( recently used ) / started using Lapua last year and been using Norma and never had high speed or pressure issues if following Nosler manual powder recommendations

300 Win Mag using H1000, CCI 250, 200 grain Accubonds, COAL 3.515" Lapua brass, 3 round groups in .4 increments:

Fouler : 76.6 grains / 3,005 fps

77.0 grains / 3041, 3075, 3068 fps

77.4 grains / 3052, 3018, 3061 fps

77.8 grains / 3096, 3025, stopped shooting

78.2 grains N/A

Speed is incredibly fast with the slow H1000 powder, ES is all over the map and I measured to the kernel using the FX-120i and expected 2900-2950 fps and grouping was not good, best is 1.25" to 1.5" @ 100. Max is 78 grains and speed should be around 2851 fps as shown in the manual and I was pushing 3,043 fps with 77.4 grains. Here is a couple of charts from QL to see what pressure I'm at. First pic is QL tweaked to use 77.4 grains with the Lapua H20 volume. The Norma brass that I used to use has a larger case volume, unlike the current Lapua brass which is 92.29 compared to 95.20. Would the case volume be the issue why its pushing too fast?

OAL is .010" off the lands, but if seating deeper, then pressure will rise as well

I may want to retry H1000 with lower charges from 74 to 76 grains which is low to mid recommendations in the Nosler manual and seat the bullets deeper to .050" off the lands since my COAL is 3.515" and the manual says max 3.340" or dump the H1000 and go back to RL 22 or RL 25 and do a ladder?