Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: this_feature_currently_requires_accessing_site_using_safari

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

carbon solvent?

- Thread starter lhsako

- Start date

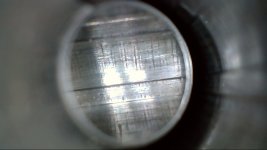

Sako, are you chasing carbon in the bore or the carbon ring build up at the front end of the chamber? No it's not brushless for carbon ring buildup, & apparently my usual cleaning regimen takes care of most carbon in the bore. See below. Picture #5 may show bore carbon buildup as the black stuff isn't visible further down the barrel.

Some history... The rifle is a 22-250 Ackley that came to me used 30 years ago as a trade-in. It shot real poorly when test fired & required a serious cleaning. Even then I considered rebarreling. No idea of the total round count, but it's pushing 800 since I've had it. This rifle has been the best learning tool I've ever owned & continues to be. It's been used, abused, brought back from the dead, & is getting tired but still shoots very well.

WW 22-250 brass shrinks c. .020"+ after fireforming in the Ackley chamber & takes about forever (8-10 full house firings) to reach max length. In the distant past I was unable to slip fit a bullet into a fired case/ Thick neck? So necks were turned to .010". After getting a Teslong bore scope the real reason became evident. It looks like the carbon ring gave a little crimp at the end of the case mouth. I believe the shorter formed case length as well as the number of firings to reach trim-to length greatly increase the carbon ring build up.

The 1st set of pics is after cleaning before carb-out. Muzzle is to the left in all pics. The next post will show Carb-out progress removing the ring.

Some history... The rifle is a 22-250 Ackley that came to me used 30 years ago as a trade-in. It shot real poorly when test fired & required a serious cleaning. Even then I considered rebarreling. No idea of the total round count, but it's pushing 800 since I've had it. This rifle has been the best learning tool I've ever owned & continues to be. It's been used, abused, brought back from the dead, & is getting tired but still shoots very well.

WW 22-250 brass shrinks c. .020"+ after fireforming in the Ackley chamber & takes about forever (8-10 full house firings) to reach max length. In the distant past I was unable to slip fit a bullet into a fired case/ Thick neck? So necks were turned to .010". After getting a Teslong bore scope the real reason became evident. It looks like the carbon ring gave a little crimp at the end of the case mouth. I believe the shorter formed case length as well as the number of firings to reach trim-to length greatly increase the carbon ring build up.

The 1st set of pics is after cleaning before carb-out. Muzzle is to the left in all pics. The next post will show Carb-out progress removing the ring.

Attachments

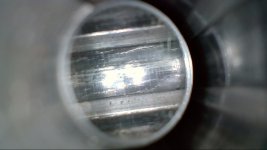

The treatment starts...

Attachments

-

carb out 7 more soak & brush.jpg337.3 KB · Views: 687

carb out 7 more soak & brush.jpg337.3 KB · Views: 687 -

carb out 6 dry again.jpg300.6 KB · Views: 687

carb out 6 dry again.jpg300.6 KB · Views: 687 -

carb out 4 no mirror c-ring 6mm brush.jpg112.3 KB · Views: 687

carb out 4 no mirror c-ring 6mm brush.jpg112.3 KB · Views: 687 -

Carb out 3 dry end of chamber step visible.jpg339.9 KB · Views: 687

Carb out 3 dry end of chamber step visible.jpg339.9 KB · Views: 687 -

carb out 2.jpg361.8 KB · Views: 687

carb out 2.jpg361.8 KB · Views: 687 -

carb out 1 6mm brush.jpg365.8 KB · Views: 687

carb out 1 6mm brush.jpg365.8 KB · Views: 687

After repeated applications & turning a 6mm brush where it stops in the chamber, using a 25 cal. brush (better fit to the problem area), a 5 hr. soak, & finally an overnight soak the ring is still there but much diminished. I may go back in & try further cleaning, but may also try other solvents. Top Engine Cleaner is next chemical in line but it's pretty toxic if my memory is working.

The whole exercise could have been a solution to a non existent problem... except for the squeezed case mouths.

The whole exercise could have been a solution to a non existent problem... except for the squeezed case mouths.

Attachments

-

carb out 16 overnight soak (3).jpg333.1 KB · Views: 681

carb out 16 overnight soak (3).jpg333.1 KB · Views: 681 -

carb out 16 overnight soak (2).jpg291.3 KB · Views: 681

carb out 16 overnight soak (2).jpg291.3 KB · Views: 681 -

carb out 15-5 hr soak still chunks.jpg321.3 KB · Views: 681

carb out 15-5 hr soak still chunks.jpg321.3 KB · Views: 681 -

carb out 14-5 hr soak getting better.jpg295.2 KB · Views: 681

carb out 14-5 hr soak getting better.jpg295.2 KB · Views: 681 -

carb out 13 25 cal brush at ring.jpg300.1 KB · Views: 681

carb out 13 25 cal brush at ring.jpg300.1 KB · Views: 681 -

carb out 11 still chunks.jpg328.1 KB · Views: 681

carb out 11 still chunks.jpg328.1 KB · Views: 681

Good write-up and photos 358 WCF. Have you tried the bathroom cleaner CLR yet? It's on my list of things to try, but I don't have a bore-cam to verify results and its acidic nature makes me leery. https://primalrights.com/library/articl ... l-cleaning and https://www.snipershide.com/shooting/th ... s.6990633/

lhsako - no direct experience with carb-out. But you did ask about the products being truly brushless. So I take it that you also want info on the patch / wipe-out products - if I am wrong please disregard the following.

For general deeper cleaning I like patch-out and wipe-out. My normal routine is to use Hoppes #9, Ballistol or other general cleaner (what ever I have at hand) after most range sessions. The patch /wipe-out comes into play closer to 100-150 rounds depending on caliber and copper fouling for an overnight cleaning and they seem to get a lot of copper and carbon out. Might take a few overnight passes, but on most of my rifles they get the gunk out. However, as 358 WCF showed, they will not address the carbon rings that show up around the lead / throat of the barrel. As such, some form of periodic abrasive (copper / bronze brush, ISSO, etc.) or acidic (CLR) cleaning is imho warranted.

FYI - some bullet jackets dissolve easily with wipe / patch-out while others bullets require another type of cleaner like M-Pro Copper or Bore-Tech copper. I've found that M-Pro Copper works when path-out doesn't and vice versa. I might be wrong here, but wipe / patch-out and M-Pro Copper work by chelation in which it bonds to a specific element or compound like Zinc. If the fouling lacks the element / compound then they are totally ineffective. Point being, if you don't get good results with patch-out / wipe-out, M-Pro Copper or other chelating bore solvents than they are probably targeted towards a different jacket composition.

lhsako - no direct experience with carb-out. But you did ask about the products being truly brushless. So I take it that you also want info on the patch / wipe-out products - if I am wrong please disregard the following.

For general deeper cleaning I like patch-out and wipe-out. My normal routine is to use Hoppes #9, Ballistol or other general cleaner (what ever I have at hand) after most range sessions. The patch /wipe-out comes into play closer to 100-150 rounds depending on caliber and copper fouling for an overnight cleaning and they seem to get a lot of copper and carbon out. Might take a few overnight passes, but on most of my rifles they get the gunk out. However, as 358 WCF showed, they will not address the carbon rings that show up around the lead / throat of the barrel. As such, some form of periodic abrasive (copper / bronze brush, ISSO, etc.) or acidic (CLR) cleaning is imho warranted.

FYI - some bullet jackets dissolve easily with wipe / patch-out while others bullets require another type of cleaner like M-Pro Copper or Bore-Tech copper. I've found that M-Pro Copper works when path-out doesn't and vice versa. I might be wrong here, but wipe / patch-out and M-Pro Copper work by chelation in which it bonds to a specific element or compound like Zinc. If the fouling lacks the element / compound then they are totally ineffective. Point being, if you don't get good results with patch-out / wipe-out, M-Pro Copper or other chelating bore solvents than they are probably targeted towards a different jacket composition.

- Thread starter

- #7

I'm looking for bore cleaning, no carbon ring removal. I find that after 10 shots I Have to patch w/ solvent, run the bronze brush, dry patch, repeat multiple times and still have a slightly dirty patch. Carb-out should do the trick. thanks for the detailed post.

- Thread starter

- #8

To be certain, this is the product you used 358 WCF ?

https://sharpshootr.com/carb-out/

https://sharpshootr.com/carb-out/

Hi Nimrod. I had seen something about CLR & forgotten completely about it. Thanks for the links.

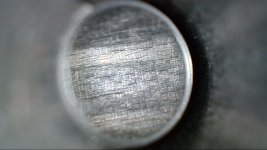

The rifle has been fired a bit since the above pics & was down in the shop soaking since yesterday. Here are 2 from today & the crusty ring is gone. Maybe it got blown down the barrel after soaking softened it? The Carb-out bottle says it helps prevent new build up as well as cleaning. So that tells me the stuff works. Maybe douching it every few hundred rounds in the future will be good maintenance.

The rifle has been fired a bit since the above pics & was down in the shop soaking since yesterday. Here are 2 from today & the crusty ring is gone. Maybe it got blown down the barrel after soaking softened it? The Carb-out bottle says it helps prevent new build up as well as cleaning. So that tells me the stuff works. Maybe douching it every few hundred rounds in the future will be good maintenance.

Attachments

Has anyone else noticed with some of the newer copper fouling reducing powders how black the patches come out & how many black patches there are when first starting to clean? Maybe it's not carbon? Maybe it's a by-product of anti-fouling?

Back in the day you could tell how a car was running by the color inside the tailpipe. Ever since unleaded gas, it's always sooty black no matter how lean the car is running.

Back in the day you could tell how a car was running by the color inside the tailpipe. Ever since unleaded gas, it's always sooty black no matter how lean the car is running.

cloverleaf

Handloader

- Sep 10, 2006

- 4,503

- 1,286

Always been satisfied with "wipe out". Only product Ive ever really used for "deep cleaning". Never needed the carbon stuff as far as I know. "Eezox" for general cleaning and rust prevention. Sold on Eezox, best rust prevention out there IMHO. CL

lhsako, Carb / Patch / Wipe-Out products should all work for you. Couple of Marines I know and one I went to school with swear by Gunzilla for carbon fouling. They were M240 / M249 gunners and they swear it changed / saved their lives in the sandbox; but I've not had great luck with it. I left mine in a car for a few weeks and I think it spoiled, it is marketed as being "plant based".

358 WCF, thank you for the follow-up. I might need to get some Carb-Out...

Yes I have seen that the newer copper fouling reducing powders leave a lot of black residue in the barrels.

Hatcher's book on the M1 Garand has about half a page on this. I believe it was the French in WWI that found that the addition of Tin waffer / foil between a cannon projectile and its powder would vaporize and bind to the copper fouling while still hot / semi-liquid in such a manner that the fouling had a greatly reduced ability to bond to the barrel. The black fouling is the amalgamated anti-copper agent and copper mixed with powder residue.

A few "tests" (which I don't have handy, but I think might be summed at: http://2poqx8tjzgi65olp24je4x4n-wpengin ... rosion.pdf) have shown decreased barrel life due to the metal in the powder eroding the lands and or rifling prematurely. However, this is formula dependent (tin, bismuth, titanium, etc) and most tests show significantly increased accuracy with less cleaning (fouling shots). And some tests show a notable increase in overall barrel life (again formula dependent).

Rule of thumb I use is that the effective / accurate round count stayed about the same or improved with the anti-copper agents in most barrels. Rough factory barrels benefited the most while premium barrels were neutral to slightly worse with the anti-copper powders. Premium barrels that were fire cracked / nearing end of life can benefit from some formulations, as the anti-copper agents fill in the cracks and cervices reducing mechanical erosion. (Filling in the cracks and crevasses might be in the Australian report above - I don't have my records handy at the moment...)

https://www.vihtavuori.com/wp-content/u ... esults.pdf

Patent overview on anti-copper agents and some of the theories behind how they work - http://www.freepatentsonline.com/EP1472199.html.

358 WCF, thank you for the follow-up. I might need to get some Carb-Out...

Yes I have seen that the newer copper fouling reducing powders leave a lot of black residue in the barrels.

Hatcher's book on the M1 Garand has about half a page on this. I believe it was the French in WWI that found that the addition of Tin waffer / foil between a cannon projectile and its powder would vaporize and bind to the copper fouling while still hot / semi-liquid in such a manner that the fouling had a greatly reduced ability to bond to the barrel. The black fouling is the amalgamated anti-copper agent and copper mixed with powder residue.

A few "tests" (which I don't have handy, but I think might be summed at: http://2poqx8tjzgi65olp24je4x4n-wpengin ... rosion.pdf) have shown decreased barrel life due to the metal in the powder eroding the lands and or rifling prematurely. However, this is formula dependent (tin, bismuth, titanium, etc) and most tests show significantly increased accuracy with less cleaning (fouling shots). And some tests show a notable increase in overall barrel life (again formula dependent).

Rule of thumb I use is that the effective / accurate round count stayed about the same or improved with the anti-copper agents in most barrels. Rough factory barrels benefited the most while premium barrels were neutral to slightly worse with the anti-copper powders. Premium barrels that were fire cracked / nearing end of life can benefit from some formulations, as the anti-copper agents fill in the cracks and cervices reducing mechanical erosion. (Filling in the cracks and crevasses might be in the Australian report above - I don't have my records handy at the moment...)

https://www.vihtavuori.com/wp-content/u ... esults.pdf

Patent overview on anti-copper agents and some of the theories behind how they work - http://www.freepatentsonline.com/EP1472199.html.

- Thread starter

- #14

Thanks for the further links Nimrod. I tried to start reading the Australian test but it's too late & me brain wont allow it. It's been downloaded for a long winter's night or something. Was just wondering out loud if that was maybe contributing to lhsako's black patch problem.

No problem 358 - it is a long theoretical read. The relevant bit is in section 3.

cha - I actually have a lot of test data available, the issue is that I don't keep it organized... I've been trying to re-find an examination of the M1 Carbine post Korean war but pre-Vietnam for several years. A friend is a big M1 Carbine fan and he asked me to send it on to him...

Having wrote that, I honestly can't find the barrel life test. It was done for the US military and looked at CHF barrels vs (I think) button rifles both types chromed and un-chromed (different barrel profiles and 5.56 and 7.62 I think) and how the interacted with several different ammo types. I have "ancillary" test data like: https://arxiv.org/ftp/arxiv/papers/1203/1203.2701.pdf which looked at lead-free vs lead primers exclusively. The basic conclusion from the full test is what I noted in my post above.

Some of the conclusions though is mentioned / addressed in other sales presentations that I am a bit more familiar with and can readily find like: https://ndiastorage.blob.core.usgovclou ... sanger.pdf page 7 notes:

Lead-free ammunition increased gun barrel wear and strong copper build-up in the barrel

Side effects can be reduced by incorporating tin dioxide into propellant

Following pages talk about bismouth being added to solve some off gassing issues the Danish had with excessive metal particles and noxious gases noted on page 9. Page 18 notes that the bismouth (C4-EL) formulation isn't causing any unusual wear patterns which I believe is addressing prior issues / concerns with tin and excessive metal wear; but might be in regards to the elevated temps & port pressure that they noted on the 5.56 testing.

The EL technology is used in some of the RL powders like RL-26 and is even noted as being in the commercial USA market on page 18. So this stuff is in the commercial / hand-loaders realm... I would think it would be in Australia, but it might be under a non-Alliant brand.

cha - I actually have a lot of test data available, the issue is that I don't keep it organized... I've been trying to re-find an examination of the M1 Carbine post Korean war but pre-Vietnam for several years. A friend is a big M1 Carbine fan and he asked me to send it on to him...

Having wrote that, I honestly can't find the barrel life test. It was done for the US military and looked at CHF barrels vs (I think) button rifles both types chromed and un-chromed (different barrel profiles and 5.56 and 7.62 I think) and how the interacted with several different ammo types. I have "ancillary" test data like: https://arxiv.org/ftp/arxiv/papers/1203/1203.2701.pdf which looked at lead-free vs lead primers exclusively. The basic conclusion from the full test is what I noted in my post above.

Some of the conclusions though is mentioned / addressed in other sales presentations that I am a bit more familiar with and can readily find like: https://ndiastorage.blob.core.usgovclou ... sanger.pdf page 7 notes:

Lead-free ammunition increased gun barrel wear and strong copper build-up in the barrel

Side effects can be reduced by incorporating tin dioxide into propellant

Following pages talk about bismouth being added to solve some off gassing issues the Danish had with excessive metal particles and noxious gases noted on page 9. Page 18 notes that the bismouth (C4-EL) formulation isn't causing any unusual wear patterns which I believe is addressing prior issues / concerns with tin and excessive metal wear; but might be in regards to the elevated temps & port pressure that they noted on the 5.56 testing.

The EL technology is used in some of the RL powders like RL-26 and is even noted as being in the commercial USA market on page 18. So this stuff is in the commercial / hand-loaders realm... I would think it would be in Australia, but it might be under a non-Alliant brand.

BruceP

Handloader

- Jun 22, 2017

- 292

- 376

What bore scope are you using? I've been thinking about one of the ones that you use with an app on your phone but haven't decided.

Bruce

Bruce

That's a bit above my paygrade Nimrod, but still interesting. I tried some of the old Barnes X bullets in the early 90s in my 338-06 & remember pushing long slivers of copper from the thrust side of the rifling out of the barrel with a tight patch afterwards. What a mess. They shot poorly, & there are still 30 in the box taking up space in the closet.

Bruce... it's this one. The semi-rigid/flexible one didn't work well for me.

https://www.amazon.com/gp/product/B081T ... UTF8&psc=1

Bruce... it's this one. The semi-rigid/flexible one didn't work well for me.

https://www.amazon.com/gp/product/B081T ... UTF8&psc=1

cloverleaf

Handloader

- Sep 10, 2006

- 4,503

- 1,286

Yup - Ive got a box of the original "X-Bullets- 1o still loaded, 30 bullets in the box. Should drill them out and use them for fishing sinkers or something. Not goin' through my rifles. CL

358 WCF":2hfj3df5 said:That's a bit above my paygrade Nimrod, but still interesting. I tried some of the old Barnes X bullets in the early 90s in my 338-06 & remember pushing long slivers of copper from the thrust side of the rifling out of the barrel with a tight patch afterwards. What a mess. They shot poorly, & there are still 30 in the box taking up space in the closet.

Bruce... it's this one. The semi-rigid/flexible one didn't work well for me.

https://www.amazon.com/gp/product/B081T ... UTF8&psc=1

Similar threads

- Replies

- 9

- Views

- 268

- Replies

- 20

- Views

- 2K