pre6422hornet

Handloader

- Jan 24, 2012

- 974

- 14

Well I finally got around to practising some checkering on some scraps of wood, so I "graduated" to one of my rifles. I grabbed the first rifle I ever bought, Marlin 60 in 22lr. It looks like it was dragged behind the truck a time or to as it was used pretty hard while racoon hunting during the mid to late 90's.

Anyway the grip panel went pretty well, but the forearm is so small I was having a tough time holding the checkering tools, while turning the stock by hand while it sat on the bench. I decided to build my own cradle.

Since I don't have a huge shop to work with, I needed it to be portable, so I could put it away when finished. I went to my checkering book by Monty Kennedy and he has pictures of quite a few and plans for one as well, but without a lathe at my disposal, I couldn't build his.

I turned to Larry Potterfield for help. You all may know Larry. He runs a small gun/reloading/hunting outfit here in Missouri... Midway USA :grin: :lol:

Seriously Larry has dozens of vids on You tube so I watched his checkering vid and paused to study his cradle:

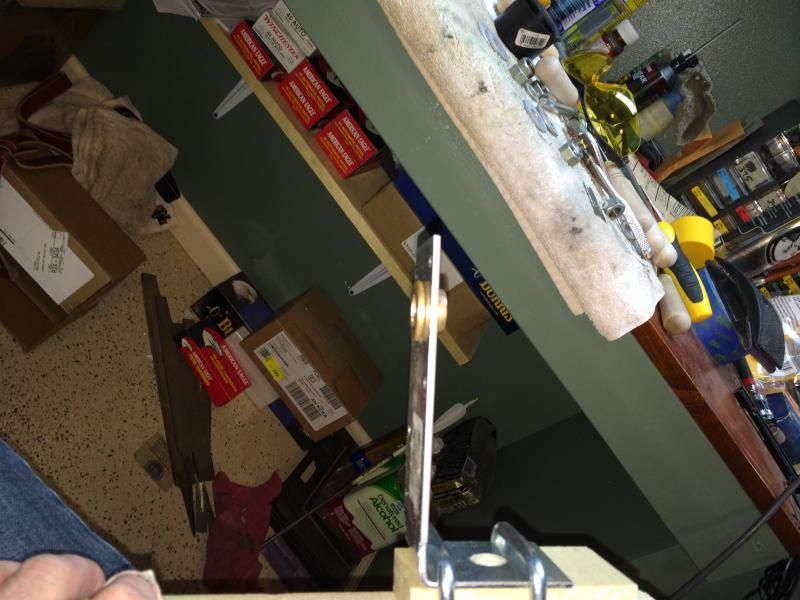

I took some notes and ran off to Lowes Sunday afternoon. 47 dollars later I returned and glued the three pieces of the base together and clamped them tight. I finished this afternoon and I think it looks pretty darn good for a Homebrew. The least expensive I could find online was 90 bucks, and the most expensice was around 300. Here it is whith the new stock for my pre 64 338 thats getting ready for inletting, pillars, sanding and bedding. .

Here is the rear box that holds the butt.

Here is the rear box that holds the butt.

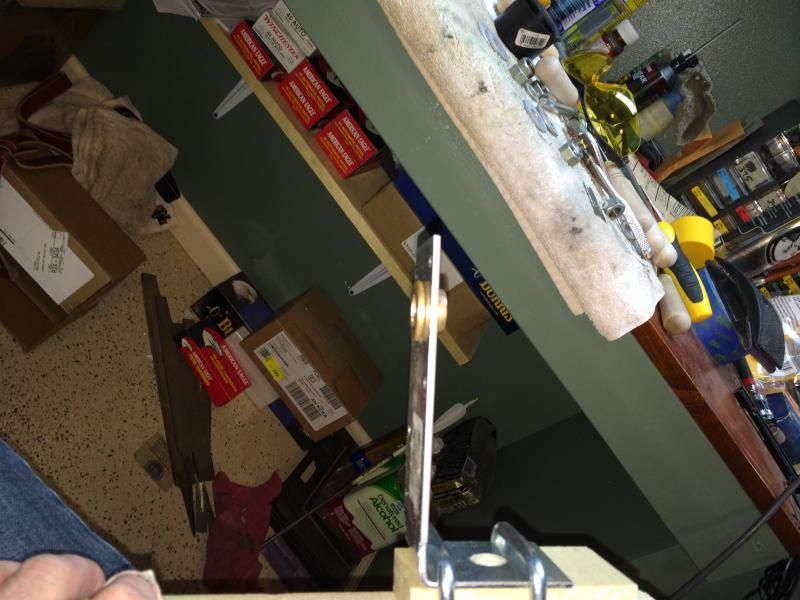

Here is how I mounted it up. I used a brass step bearing that allows the bolt to rotate freely, yet I can tighten it down against the locking washer to keep the stock in place for intricate work. I had to grind out ht e1/2 inch hole to an ID of 3/4 inch , then put the brass bearing in the freezer fora bit and heated up the hole with a torch and she slid right in..

the front of the cradle is basically a 2 inch PVC cap bolted on.

I look forward to getting some work done real soon.

Anyway the grip panel went pretty well, but the forearm is so small I was having a tough time holding the checkering tools, while turning the stock by hand while it sat on the bench. I decided to build my own cradle.

Since I don't have a huge shop to work with, I needed it to be portable, so I could put it away when finished. I went to my checkering book by Monty Kennedy and he has pictures of quite a few and plans for one as well, but without a lathe at my disposal, I couldn't build his.

I turned to Larry Potterfield for help. You all may know Larry. He runs a small gun/reloading/hunting outfit here in Missouri... Midway USA :grin: :lol:

Seriously Larry has dozens of vids on You tube so I watched his checkering vid and paused to study his cradle:

I took some notes and ran off to Lowes Sunday afternoon. 47 dollars later I returned and glued the three pieces of the base together and clamped them tight. I finished this afternoon and I think it looks pretty darn good for a Homebrew. The least expensive I could find online was 90 bucks, and the most expensice was around 300. Here it is whith the new stock for my pre 64 338 thats getting ready for inletting, pillars, sanding and bedding. .

Here is the rear box that holds the butt.

Here is the rear box that holds the butt. Here is how I mounted it up. I used a brass step bearing that allows the bolt to rotate freely, yet I can tighten it down against the locking washer to keep the stock in place for intricate work. I had to grind out ht e1/2 inch hole to an ID of 3/4 inch , then put the brass bearing in the freezer fora bit and heated up the hole with a torch and she slid right in..

the front of the cradle is basically a 2 inch PVC cap bolted on.

I look forward to getting some work done real soon.