There had been some discussion over the winter and spring on the forum concerning Tubb's Final Finish bullets. I had been curious about these and decided to try them on a factory Winchester barrel from the New Haven factory in the 2005-2006 time frame. The rifle is a left-handed M70 chambered in 300 WSM. The bore was very rough and fouled quickly. It even had metal chips pressure welded to surface of bore. It would shoot a good group sometimes but I couldn't duplicate a group from one shooting session to another. It seemed as if a good group could only be shot between about the fifth shot and the 12th shot.

I purchased the 50 bullet set and cleaned the rifle bore until all the copper was removed. The directions recommended a thorough cleaning after each set of 10 bullets. However, I figured that any copper in the bore would not allow the abrasives on the bullet to actually treat the bore. So, I cleaned the bore after every 5 shots. That added a lot of extra work but at least I was assured that each grit of bullet went through a clean bore twice.

I used a new target for each five bullets and during the course of the process, I actually shot a couple of fairly decent groups.

I could tell the process was having an effect. First, I could feel the difference when running patches through the bore. The bore felt smoothly after just the first ten bullets and continued to feel smoother has the process progressed. Secondly, you could see the groups change as the leads to the lands wore.

The Base-to-Ogive (BTO) changed (due to wear) differently for different shaped bullets. The more tapered bullets showed the greater increase in BTO. The Hornady 180 SP showed only a .010" increase in the BTO. The 165 grain BT's and AB's showed about .025" to .030" increase in BTO. The 180 gr. AB's and Sierra SBT's showed about .031" to .035" increase in BTO.

Here are some before and after photos.

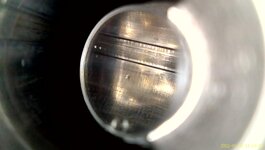

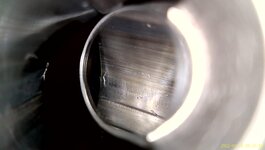

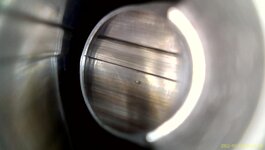

This is an area with a small chip pressure welded before the treatment.

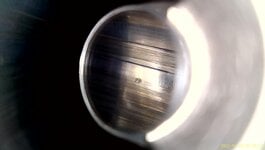

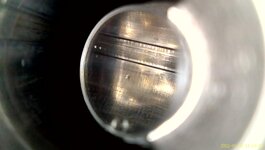

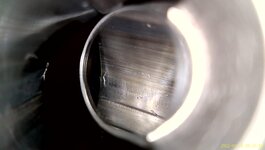

This is the same area after the process.

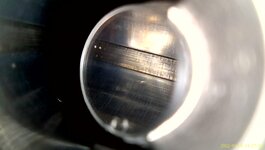

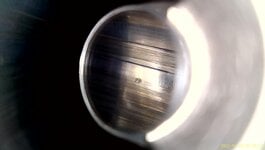

This is another area with a small chip before the process.

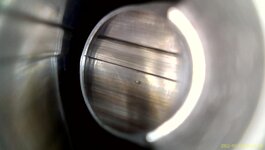

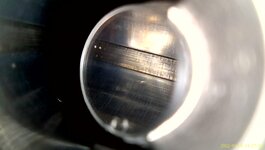

Here is the same area after.

Here is area near the muzzle before the process.

Here is the same area after.

I think the photos speak for themselves.

As the accuracy, I was able to shoot these groups afterward.

As you can see, except for the first fouling shot, it shot pretty good. I would be comfortable taking this hunting.

Overall, I believe the Tubb's Final Finish Bullets helped this barrel. I would use them again in a similar situation.

Dan

I purchased the 50 bullet set and cleaned the rifle bore until all the copper was removed. The directions recommended a thorough cleaning after each set of 10 bullets. However, I figured that any copper in the bore would not allow the abrasives on the bullet to actually treat the bore. So, I cleaned the bore after every 5 shots. That added a lot of extra work but at least I was assured that each grit of bullet went through a clean bore twice.

I used a new target for each five bullets and during the course of the process, I actually shot a couple of fairly decent groups.

I could tell the process was having an effect. First, I could feel the difference when running patches through the bore. The bore felt smoothly after just the first ten bullets and continued to feel smoother has the process progressed. Secondly, you could see the groups change as the leads to the lands wore.

The Base-to-Ogive (BTO) changed (due to wear) differently for different shaped bullets. The more tapered bullets showed the greater increase in BTO. The Hornady 180 SP showed only a .010" increase in the BTO. The 165 grain BT's and AB's showed about .025" to .030" increase in BTO. The 180 gr. AB's and Sierra SBT's showed about .031" to .035" increase in BTO.

Here are some before and after photos.

This is an area with a small chip pressure welded before the treatment.

This is the same area after the process.

This is another area with a small chip before the process.

Here is the same area after.

Here is area near the muzzle before the process.

Here is the same area after.

I think the photos speak for themselves.

As the accuracy, I was able to shoot these groups afterward.

As you can see, except for the first fouling shot, it shot pretty good. I would be comfortable taking this hunting.

Overall, I believe the Tubb's Final Finish Bullets helped this barrel. I would use them again in a similar situation.

Dan