Desert Fox

Handloader

- Aug 14, 2006

- 1,965

- 4

I have just finished reloading 45 rounds for my 6.5-284 (25 Sierra 142 grain SMK and 20 Berger 140 VLD Target) today. I'm still in a process of load development trying to squeezed more fps out of the 26" Lothar. By the way thanks to the kindness of Powerstroke for sending me the Berger all the way from Colorado. He even paid for the postage,.."What a guy". Thank you Mark. I hope I can return the favor someday.

Anyway, while at it, I started sorting the loaded round by measuring bullet run-out and I noticed that out of 25 Sierras that I measured only 8 made it into the .001" to.002" range and the rest between .003" - .007". I began to suspect the Lapua brass until I got to measuring the Bergers. Out of 20 loaded case, 13 are within .001"-.002" range and the rest measured no more than .004". Now the brass came from the same lot and I haven't measured the wall thickness yet. I'll do that after the first firing and neck sizing. So I assumed the cause of the extreme runout on the Sierra must have come from the bullet. What do you think Guys? DF

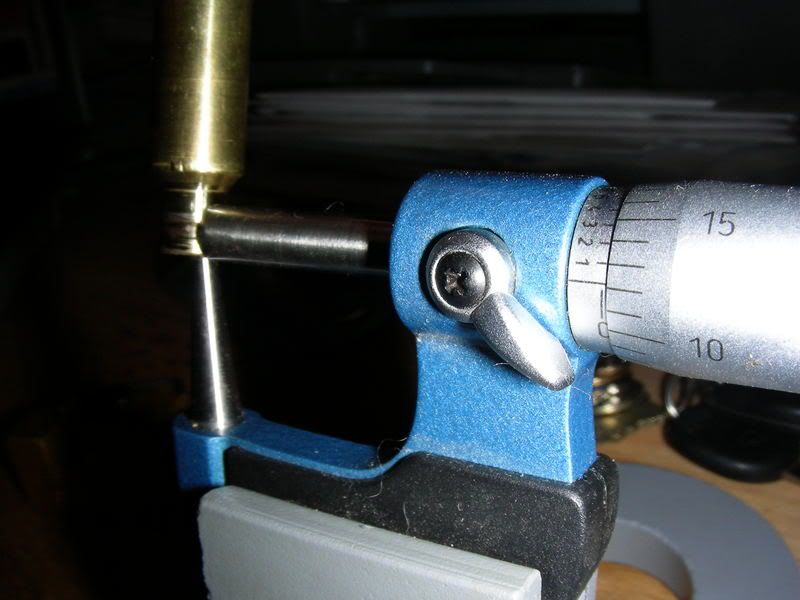

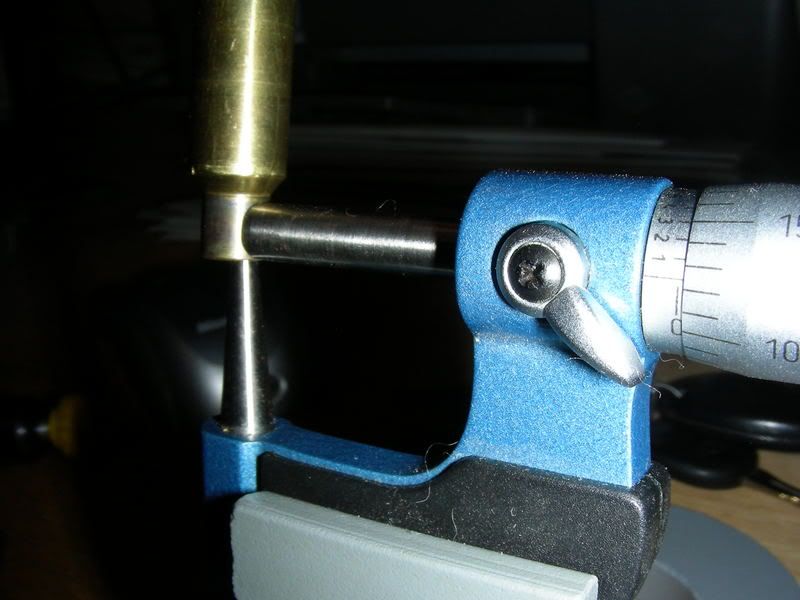

Here's the loaded round. The Berger on the right.

Anyway, while at it, I started sorting the loaded round by measuring bullet run-out and I noticed that out of 25 Sierras that I measured only 8 made it into the .001" to.002" range and the rest between .003" - .007". I began to suspect the Lapua brass until I got to measuring the Bergers. Out of 20 loaded case, 13 are within .001"-.002" range and the rest measured no more than .004". Now the brass came from the same lot and I haven't measured the wall thickness yet. I'll do that after the first firing and neck sizing. So I assumed the cause of the extreme runout on the Sierra must have come from the bullet. What do you think Guys? DF

Here's the loaded round. The Berger on the right.