300WSM

Handloader

- Dec 24, 2011

- 1,293

- 909

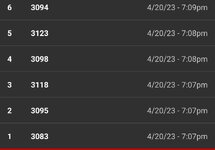

How much will differing case mfg impact velocity?

I did this test with three different case mfg's...

All trimmed to same length!

Bullet seated same depth!

Same powder and exact charge!

Same #41 primer

Shot in random order to further magnify the variances...

As if someone just grabbed miscellaneous brass and loaded up and hunted and or shooting a group...

Significant or insignificant?

Only you the shooter could answer that but I can say 100 fps as a rule of thumb will differ approximately 1"-1.5" for a 30 cal with a 180 gr bullet at 500 yards all things being equal

Where as a 22 cal with a simple 55gr FMJ/BT will see a 2.5"-3" difference at 500 yards all things being equal.

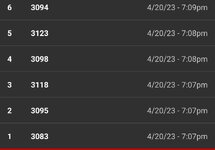

I did this test with three different case mfg's...

All trimmed to same length!

Bullet seated same depth!

Same powder and exact charge!

Same #41 primer

Shot in random order to further magnify the variances...

As if someone just grabbed miscellaneous brass and loaded up and hunted and or shooting a group...

Significant or insignificant?

Only you the shooter could answer that but I can say 100 fps as a rule of thumb will differ approximately 1"-1.5" for a 30 cal with a 180 gr bullet at 500 yards all things being equal

Where as a 22 cal with a simple 55gr FMJ/BT will see a 2.5"-3" difference at 500 yards all things being equal.