boomer68

Handloader

- Oct 23, 2006

- 883

- 91

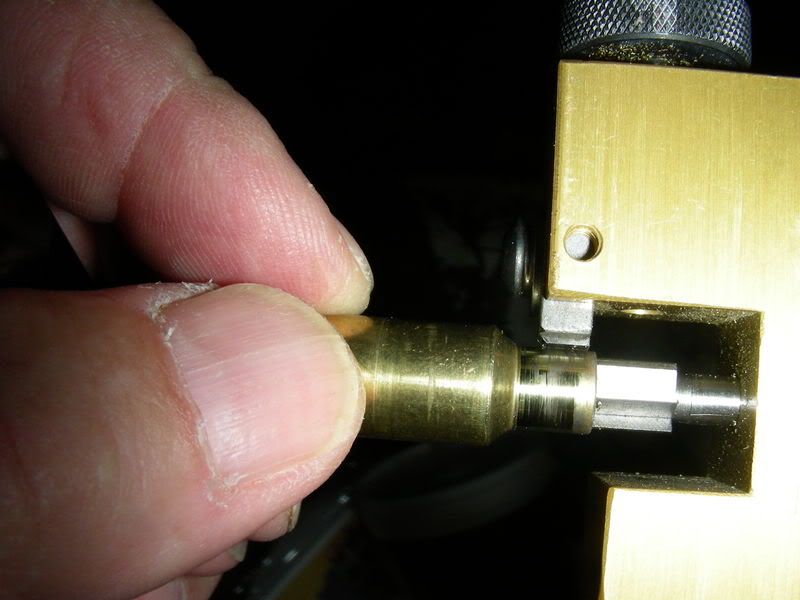

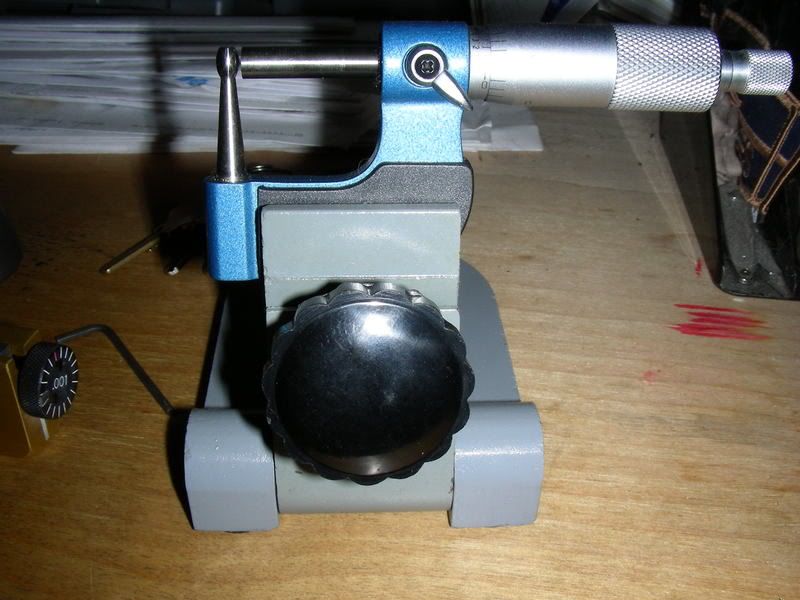

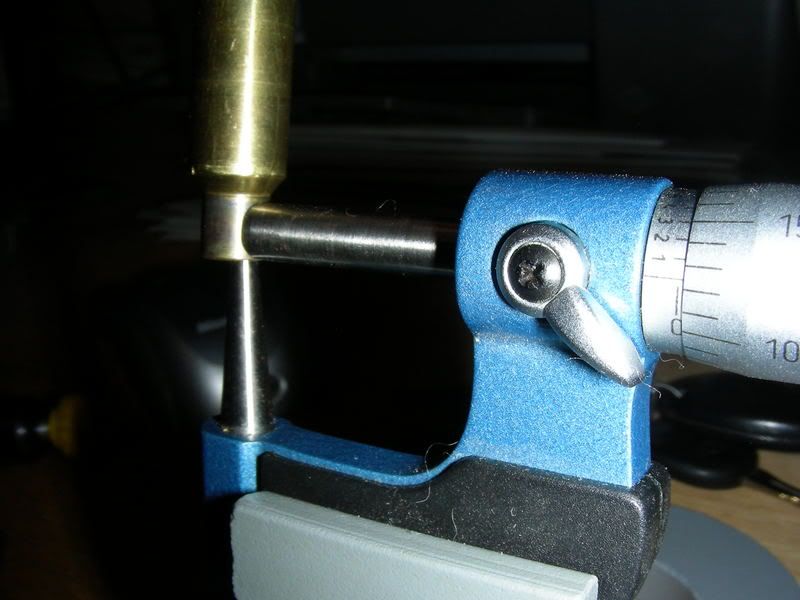

On the subject of neck turning, what is a good tool to use? I would be looking at getting one.

Another item that seems popular is the flash hole deburring tool.

Another item that seems popular is the flash hole deburring tool.