Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: this_feature_currently_requires_accessing_site_using_safari

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

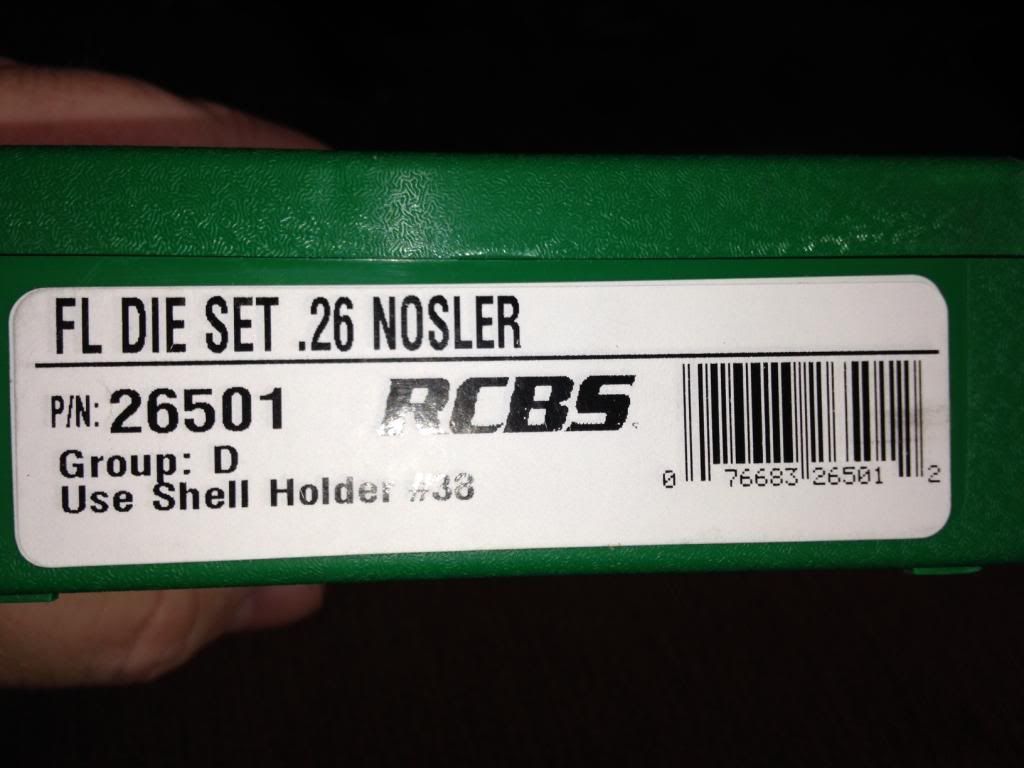

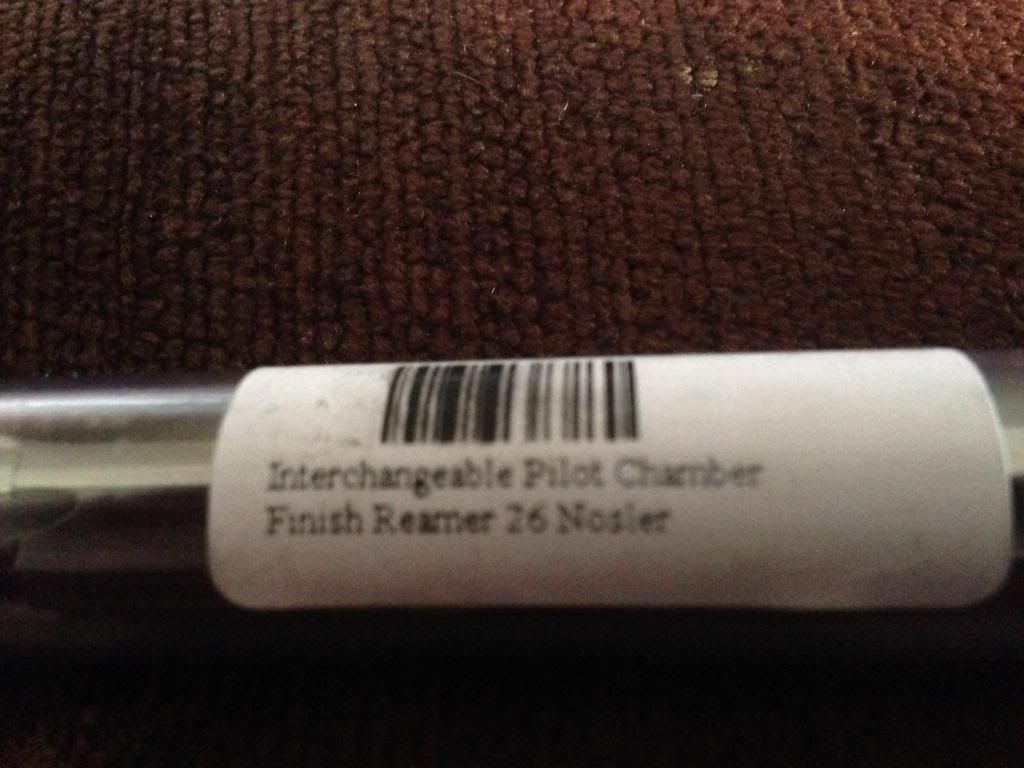

The pieces are coming together

- Thread starter muleman

- Start date

gerry

Ammo Smith

- Mar 1, 2007

- 6,908

- 1,791

I'm amazed that dies are already out, looking forward to how your project works out.

longwinters

Handloader

- Oct 10, 2004

- 1,476

- 1

Sweet, I can live vicariously though you as this all comes together.....

Long

Long

- Nov 4, 2004

- 25,342

- 8,903

Scott,

Well done buddy.

Brave New Strangers.....

JD338

Well done buddy.

Brave New Strangers.....

JD338

- Thread starter

- #6

In the last couple of days I've read the two articles about the 26Nosler; in Guns & Ammo and Shooting Times respectively. To be honest, I was disappointed in them. The 26Nosler received good reviews and seems to perform very well. I was disappointed in the lack of range work and load info. Well I guess they had limited ammo and it was last November. I'm looking forward to Nosler releasing some load info so I can start some work ups. I'll be able to load the cartridges long and hopefully not impinge to much into the case. The rumor I heard is that brass will be available in the next few weeks. If I don't see any load data by the time brass is available I'll start with reduced 6.5STW loads since it's pretty close in capacity. I've got RL25, RL33, Retumbo, H1000, H50BMG, 7828, 869 and 4831. I'm hoping that one or several of them prove to be the magic key. I'd like use the 129LRAB and the 140gr AB. If those don't fly I'll try the 140gr Scirroco.

There is always hope that Nosler will come out with a heavier LRAB!

There is always hope that Nosler will come out with a heavier LRAB!

nvbroncrider

Handloader

- Aug 20, 2011

- 3,085

- 4

I imagine one of the guys with QL could load the info from the reamer drawing and get you some close approximations of where you will be.

- Thread starter

- #9

- Nov 4, 2004

- 25,342

- 8,903

Scott,

Do you have a barrel ordered?

JD338

Do you have a barrel ordered?

JD338

- Thread starter

- #11

JD338":3ql3m8qj said:Scott,

Do you have a barrel ordered?

JD338

Jim,

Yes, I've ordered a 31" Bartlein5R in a Light Palma - Planning to finish it at 28" leaving room to set back in case I torch the throat faster than anticipated. I'm also hoping to see a 140 or heavier ABLR put out by Nosler :wink:

Scott

- Nov 4, 2004

- 25,342

- 8,903

Scott,

Good choice on the barrel and glad you are going 28". That will

allow you 1-2 set backs.

Can't wait for you to get it all put together.

JD338

Good choice on the barrel and glad you are going 28". That will

allow you 1-2 set backs.

Can't wait for you to get it all put together.

JD338

- Thread starter

- #16

Scotty,

I believe Nathan is referencing the straight section/amount of initial taper of barrel. On the Bartlein light Palma it starts out at 3" before threading and chambering. Any successive chambering would continue to set that initial shank even shorter and at some point you run out of available shank.???? I'm sure Nathan will be along soon to enlighten us.

Scott

I believe Nathan is referencing the straight section/amount of initial taper of barrel. On the Bartlein light Palma it starts out at 3" before threading and chambering. Any successive chambering would continue to set that initial shank even shorter and at some point you run out of available shank.???? I'm sure Nathan will be along soon to enlighten us.

Scott

Yes you really need at least 2" of shank to enclose the cartridge (remember it is 2.59" long?), have enough to thread, and enough to grab a hold of with the lathe. That is why most barrels are at least that long at the flat section before they start to taper. So if you cook the barrel too much (and by the time the throat starts to get longer it's too much on a hot rod like the 26) you will only have 1" to set it back versus another barrel that has a longer flat section. Basically you don't want the section where the highest pressure is to be down in the smaller section of the barrel for safety sake. The further down the barrel the bullet goes the lower the pressure is and that is why it is OK to taper barrels to pretty thin dimensions at the muzzle.

nvbroncrider

Handloader

- Aug 20, 2011

- 3,085

- 4

Silly comment on this. Why does Winchester only use a 1/4" maybe a 1/2" shank on their FW contour barrel then? I know it drops weight but if that was supposed to ensure integrity wouldn't that be a liability issue?

I think they only do it in non magnum or really short magnum (WSM's) cases. Since there is roughly 7/8" in the action and the smaller flat the majority of the case is covered. Winchesters run thin everywhere it seems since they are only 1" threads where as most a 1 1/16". That leaves a thinner wall between the chamber and the threads. Then they do the crazy step down taper on the feather weights. I think they only do that in chromoly barrels. A lot of barrel companies won't run as small of a contour in stainless as they will with chromoly because stainless doesn't handle the cold as well.