Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: this_feature_currently_requires_accessing_site_using_safari

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Boyds on EBAY

- Thread starter chet

- Start date

- Oct 30, 2004

- 24,625

- 4,084

Nice snag?

- Thread starter

- #3

- Nov 4, 2004

- 26,202

- 11,648

chet

Nice!

Congratulations on your new stock.

JD338

Nice!

Congratulations on your new stock.

JD338

DrMike

Ballistician

- Nov 8, 2006

- 37,823

- 7,555

Attractive stock. Once it is on the rifle, give us a picture.

6mm Remington

Ammo Smith

- Feb 27, 2006

- 5,304

- 825

Chet

That was great purchase. They build a really nice stock. I put one on my son's 6mm Remington in a Ruger MKII. I had it glass and pillar bedded, and it shoots great. I also had a gal that does checkering do a fine job of checkering it for him. It really helps as they are nice, but a touch slick with gloves on and snow on the gloves. Great stocks!

That was great purchase. They build a really nice stock. I put one on my son's 6mm Remington in a Ruger MKII. I had it glass and pillar bedded, and it shoots great. I also had a gal that does checkering do a fine job of checkering it for him. It really helps as they are nice, but a touch slick with gloves on and snow on the gloves. Great stocks!

- Thread starter

- #7

6mm Remington

Ammo Smith

- Feb 27, 2006

- 5,304

- 825

Now that looks great. Sure looks like you know what you are doing. You will love that stock for sure. The laminates to me are so beautiful and each one looks slightly different. They have the best of both worlds. They have that warm look and feel of wood with the strength of a sythetic with an aluminum bedding block. Cannot beat it!

- Thread starter

- #9

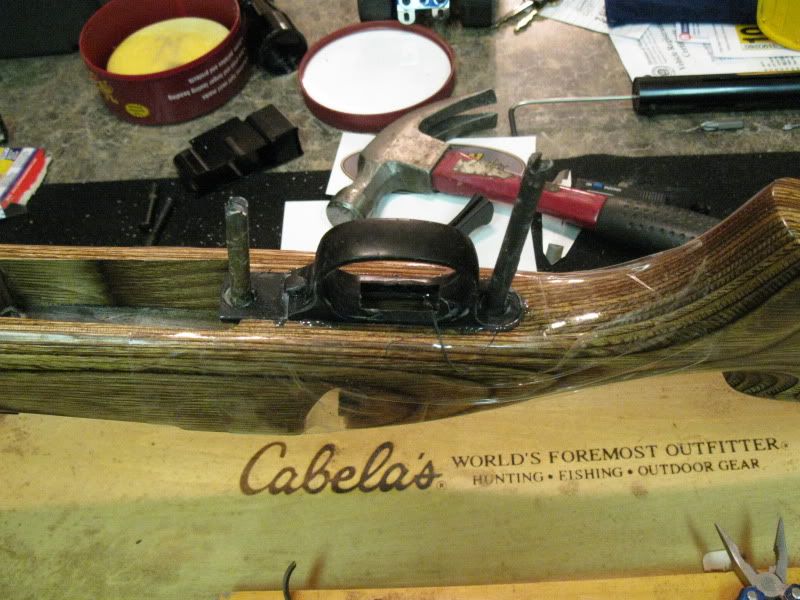

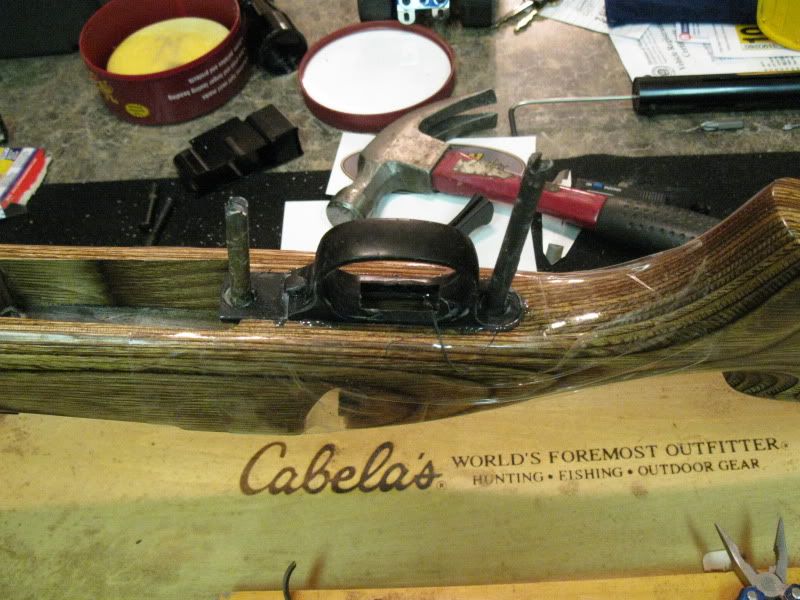

bottom half is finished.

I don't use aluminum pillars.

I enlarge the screw holes to approx 5/8 inch and fill and bed half at a time to keep things lined up.

Next I'll widdle away the screw holes from the top until I run into the bedding that I drizzled in from the bottom.

I'm using prematex cold weld, it ends up harder than aluminum, has a shear strength of 3000 psi and is the most resistant to the solvents that us shooters use. I have used pillars before, but this way is much easier and ends up more precise, at least for me.

I don't use aluminum pillars.

I enlarge the screw holes to approx 5/8 inch and fill and bed half at a time to keep things lined up.

Next I'll widdle away the screw holes from the top until I run into the bedding that I drizzled in from the bottom.

I'm using prematex cold weld, it ends up harder than aluminum, has a shear strength of 3000 psi and is the most resistant to the solvents that us shooters use. I have used pillars before, but this way is much easier and ends up more precise, at least for me.

- Thread starter

- #10

- Nov 4, 2004

- 26,202

- 11,648

chet,

Lookin' good!

JD338

Lookin' good!

JD338

- Thread starter

- #12

Scott Spencer

Handloader

- Mar 27, 2008

- 525

- 0

Awesome, Chet!! Keep us posted and keep posting the progress pics!

- Thread starter

- #14

- Thread starter

- #15

ACLakey

Beginner

- Aug 11, 2008

- 161

- 0

Good work, any update on the accuracy improvements?

- Thread starter

- #17

Chet, I noticed you have quite a bit of epoxy at the tang area, just make sure you don't inhibit rearward motion at this point! I had a JRS nutmeg on my model 70 bedded much the same as yours and broke it out behind the tang from bedding that acted like a recoil lug back there. Put some clearance behind the metal around the rear bolt. Mine shot well under an inch till I cracked it. Boyd's replaced it free of charge, even though it was my fault! Evidently the action grows in length as it warms up, putting pressure at this point if it's tight!

good luck with the project!

good luck with the project!

- Thread starter

- #19