Creedmore,

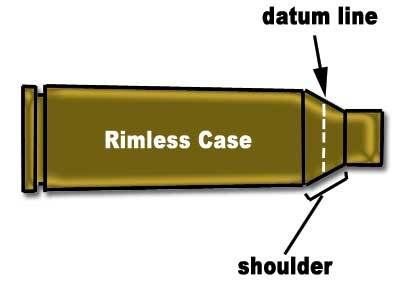

There's one more situation that can cause head separations and appear as a headspace issue when it's not. If your chambers base is wider than the brass being used, the brass will expand and stretch to fit the chamber, resizing it then brings it back, firing makes it stretch again and the brass usually lets go somewhere between shots 2 and 5 depending on how hot your loads are.

This issue is most prevalent in European chamberings like say the 6.5x55 primarily because US manufacturers insisted on making brass with a solid head size of 0.471" (and dies that match) when the true European specs are 0.480". Firing US brass in a Euro spec'd chamber and reloading it using dies made to US specs caused all sorts of trouble. Not sure if that's still the case though.

It's not relevant to your issue though as you've measured the brass as having grown in length rather than circumference, but its worth keeping in mind.

Cheers...

Con

There's one more situation that can cause head separations and appear as a headspace issue when it's not. If your chambers base is wider than the brass being used, the brass will expand and stretch to fit the chamber, resizing it then brings it back, firing makes it stretch again and the brass usually lets go somewhere between shots 2 and 5 depending on how hot your loads are.

This issue is most prevalent in European chamberings like say the 6.5x55 primarily because US manufacturers insisted on making brass with a solid head size of 0.471" (and dies that match) when the true European specs are 0.480". Firing US brass in a Euro spec'd chamber and reloading it using dies made to US specs caused all sorts of trouble. Not sure if that's still the case though.

It's not relevant to your issue though as you've measured the brass as having grown in length rather than circumference, but its worth keeping in mind.

Cheers...

Con