The extra time off right now is spurring me to take care of a few things that have been on the back burner until now.

Got a Remington 141 in 35 Remington I really like but the trigger was super heavy, I didn't check it prior but I'm guessing at least 8 lbs. I felt like it was getting worse the last few times I shot it, but that might of just been in my head as when I took it apart I seen nothing in the way of corrosion or anything that would've caused it to be any different.

Quite a project but in the end well worth it as the trigger is now so much better. Plus I learned new information as it relates to this particular model rifle.

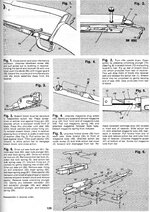

Completely disassembled the bolt to get at the sear face, and the firing pin face the sear notch latches over.

The level of craftsmanship and tight tolerances of all the intricate parts in some of these old rifles never ceases to amaze me. Every piece was milled back then. Stamped parts were not yet part of rifle manufacturing process, and was at a time when they would've been scoffed at had they been. This particular rifle appears to be a 1936 model.

Pure quality throughout. Case hardened internal parts, complicated ingenious designs that had to be very time consuming to produce. Just a Remington pump rifle, but to produce an exact copy today using the same quality manufacturing of all milled parts, would cost thousands of dollars. Even the loading gate on this rifle is case hardened. Didn't need to be, but another A+ for doing so.

Anyways here's the disassembled bolt with the parts cleaned up after the sear and firing pin face work. Took everything out but the extractor, which I did after the fact and discovered I should find a new extractor spring to replace it before the upcoming hunting season.

Here's a pic of the old rifle. Fun rifle to shoot and has been very accurate with factory Remington 200 gr cor lokts. Hope to test the effectiveness of a 35 Remington on a whitetail with this rifle soon.

Got a Remington 141 in 35 Remington I really like but the trigger was super heavy, I didn't check it prior but I'm guessing at least 8 lbs. I felt like it was getting worse the last few times I shot it, but that might of just been in my head as when I took it apart I seen nothing in the way of corrosion or anything that would've caused it to be any different.

Quite a project but in the end well worth it as the trigger is now so much better. Plus I learned new information as it relates to this particular model rifle.

Completely disassembled the bolt to get at the sear face, and the firing pin face the sear notch latches over.

The level of craftsmanship and tight tolerances of all the intricate parts in some of these old rifles never ceases to amaze me. Every piece was milled back then. Stamped parts were not yet part of rifle manufacturing process, and was at a time when they would've been scoffed at had they been. This particular rifle appears to be a 1936 model.

Pure quality throughout. Case hardened internal parts, complicated ingenious designs that had to be very time consuming to produce. Just a Remington pump rifle, but to produce an exact copy today using the same quality manufacturing of all milled parts, would cost thousands of dollars. Even the loading gate on this rifle is case hardened. Didn't need to be, but another A+ for doing so.

Anyways here's the disassembled bolt with the parts cleaned up after the sear and firing pin face work. Took everything out but the extractor, which I did after the fact and discovered I should find a new extractor spring to replace it before the upcoming hunting season.

Here's a pic of the old rifle. Fun rifle to shoot and has been very accurate with factory Remington 200 gr cor lokts. Hope to test the effectiveness of a 35 Remington on a whitetail with this rifle soon.