joelkdouglas

Handloader

- Jun 5, 2011

- 1,310

- 7

Scotty I think you and I were having the same problem, trying to get some excellent concentricity out of our 7 Mashburn ammo. I think I have it figured, at least for today. I read about this O Ring trick at Accurate Shooter some time ago, but I was screwing the die into the press too tight. The worst concentricity I have out of these is 0.004:

The blue sharpie marked round was the first round seated, seating depth a bit too deep. It'll be a good zero check round. Oops!

It doesn't usually take me much effort to get near perfect concentricity. If you want a sure fire method, just resize cases with either a Lee Collet die and Redding Body die, or a Redding Competition Neck Sizing die and a Redding Body die. Forster bushing dies with the neck opened up per their custom service is also a good way to go. All those sets of dies will produce near perfect brass after sizing. Then take a Redding or Forster Competition micrometer seater die and presto, near perfect ammo. The sliding sleeve supports the case thoughout the sizing or seating operation, and though pricey they are great.

Well none of that is available for a 7 Mashburn. All the dies are custom, and Redding doesn't make a sliding sleeve sizing or seating die for it. Forster doesn't make a die at all. Redding will make a custom Type S bushing sizing die, but those are so-so for concentricity, about 0.002 to 0.004, then add the error from your sizing die and it gets tough to achieve the 0.005 or less standard (or whatever you prefer, for hunting that's my standard).

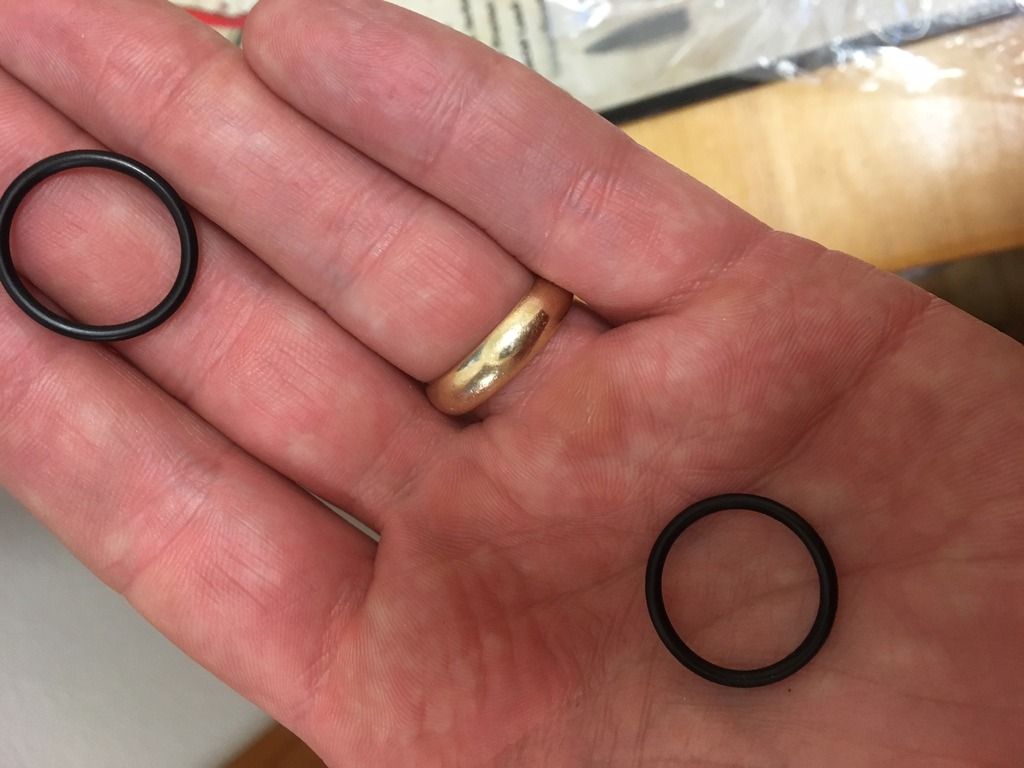

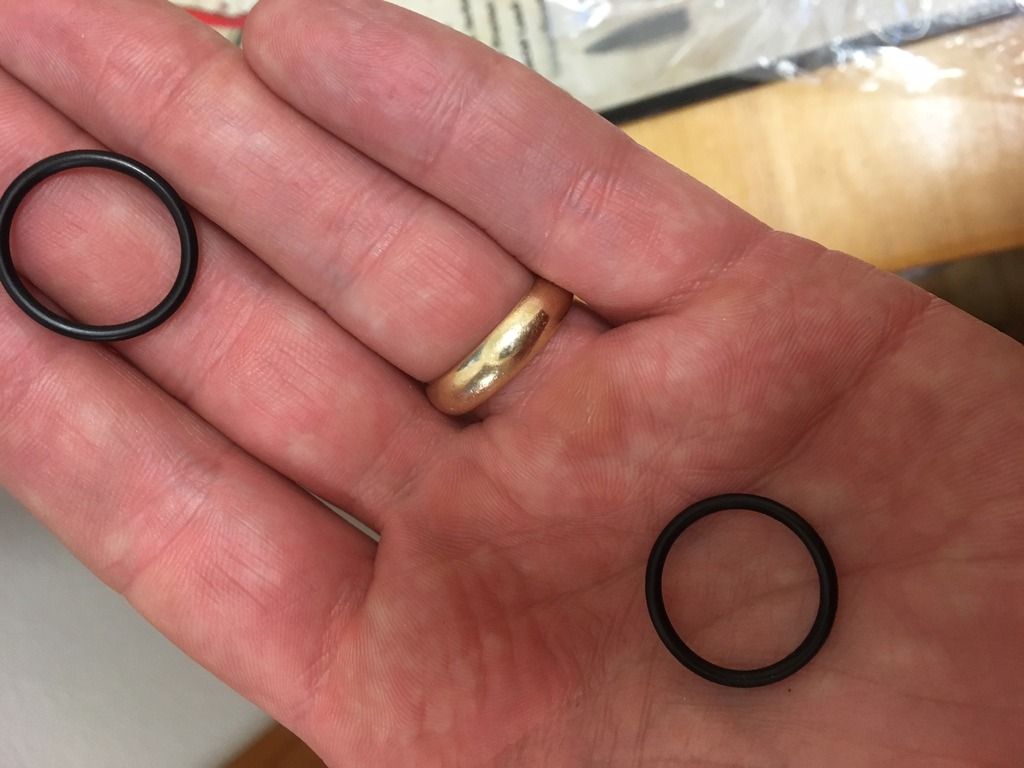

But I hadn't given up yet. I took one of these:

And put it on the dies like this:

Then screw the die into the press but still has a bit of room to "wiggle", and they kind of let the die align with the ram and case. Oh, and use a shellholder that has some room for wiggle in it too, like Reddings. The Lee shellholder holds the case too tight I think.

This is the worst loaded round:

This is the best loaded round, pretty much no needle movement at all:

Scotty I threw a handful of these O rings into my stuff to bring to Wyoming. I'll give you and Matt some there. You can try it out and see if you can save money and not buy other dies.

The blue sharpie marked round was the first round seated, seating depth a bit too deep. It'll be a good zero check round. Oops!

It doesn't usually take me much effort to get near perfect concentricity. If you want a sure fire method, just resize cases with either a Lee Collet die and Redding Body die, or a Redding Competition Neck Sizing die and a Redding Body die. Forster bushing dies with the neck opened up per their custom service is also a good way to go. All those sets of dies will produce near perfect brass after sizing. Then take a Redding or Forster Competition micrometer seater die and presto, near perfect ammo. The sliding sleeve supports the case thoughout the sizing or seating operation, and though pricey they are great.

Well none of that is available for a 7 Mashburn. All the dies are custom, and Redding doesn't make a sliding sleeve sizing or seating die for it. Forster doesn't make a die at all. Redding will make a custom Type S bushing sizing die, but those are so-so for concentricity, about 0.002 to 0.004, then add the error from your sizing die and it gets tough to achieve the 0.005 or less standard (or whatever you prefer, for hunting that's my standard).

But I hadn't given up yet. I took one of these:

And put it on the dies like this:

Then screw the die into the press but still has a bit of room to "wiggle", and they kind of let the die align with the ram and case. Oh, and use a shellholder that has some room for wiggle in it too, like Reddings. The Lee shellholder holds the case too tight I think.

This is the worst loaded round:

This is the best loaded round, pretty much no needle movement at all:

Scotty I threw a handful of these O rings into my stuff to bring to Wyoming. I'll give you and Matt some there. You can try it out and see if you can save money and not buy other dies.