I am not sure if this will be useful for any one or not, but with the 7mm Mashburn Super Magnum you sometimes get donuts when necking down 300 Win Mag brass. The extra brass accumulates around the bottom of the neck on the inside of the case. Well, I am not a neck turner nor have I ever, but with that donut getting completely straight rounds is pretty tough. Anyhow a few of us were tipped off by Darcy Echols to invest in some pin gauges to detect the donuts and also to use them to get your neck tension measurements.

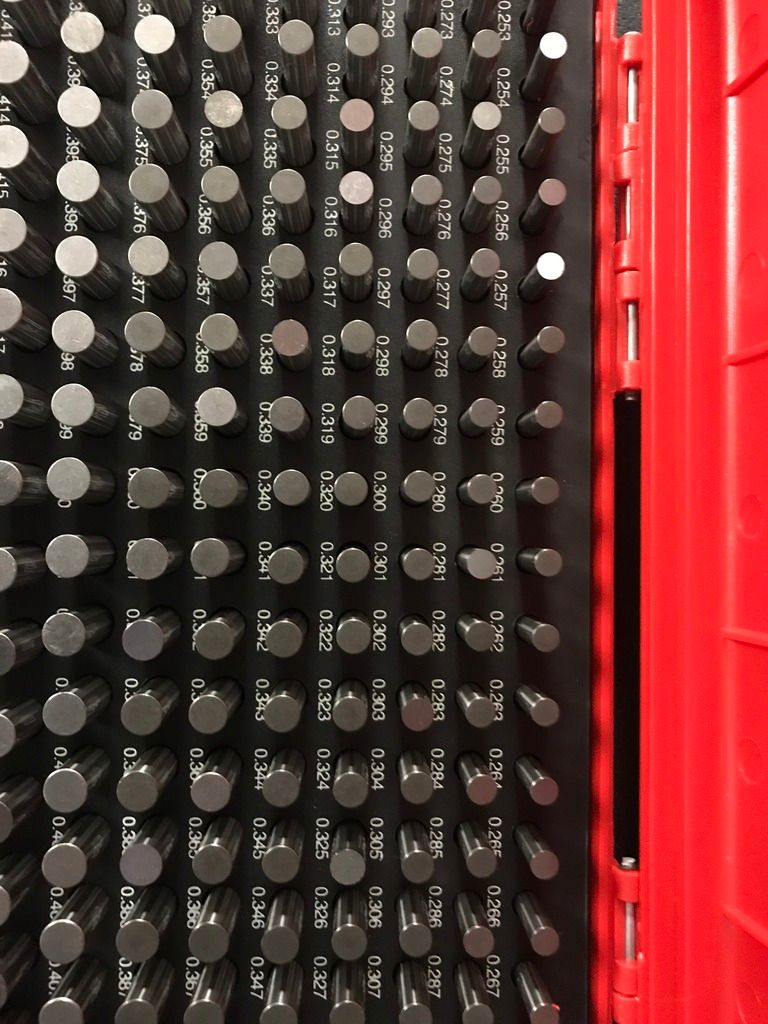

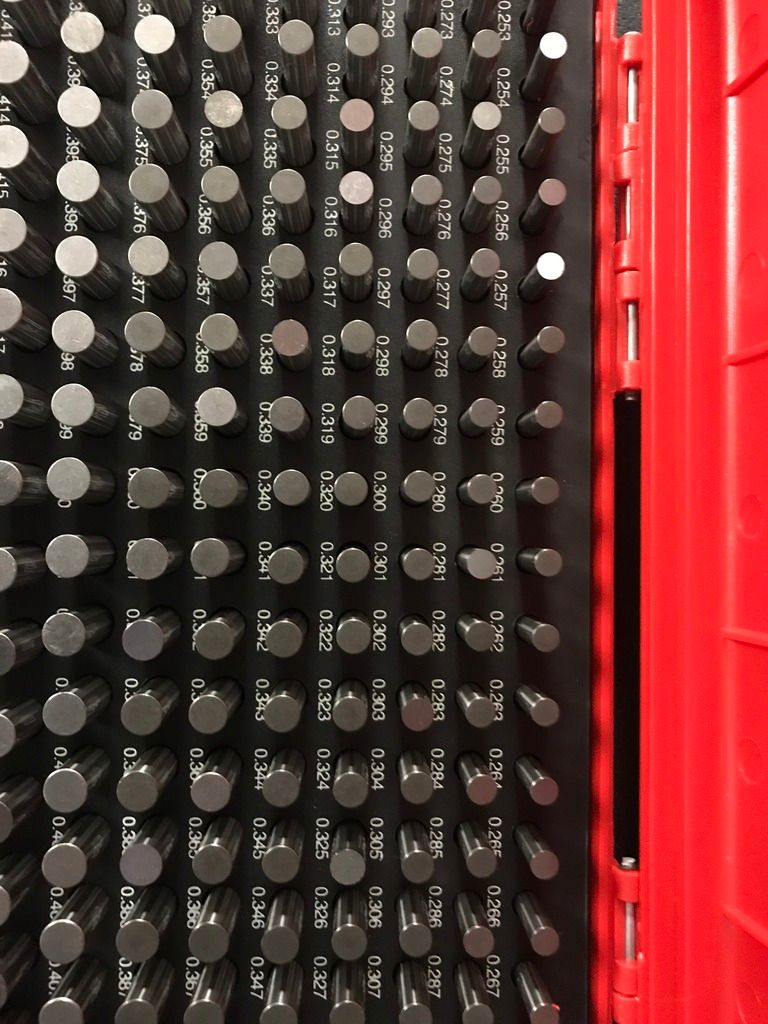

Here is a picture of the pin gauges. Mine start from .250 and go up to .500.. I'll have to get a 2nd set of the small ones up to the .250 side. In reality, I need all of them in the middle of the two sets.. Oh well, they aren't alot of money but man have they schooled me on some things I'd never thought about.

Here are a couple of pictures of what I am talking about forming the donut without really knowing it is there.

There is a 300 Win on the left and a 7mm Mashburn on the right after going through the form and trim die..

This is a picture of a 160 Swift A-Frame that is stopped by the donut. The bullet will fall through the neck until it hits the donut and stop. Of course if I wanted to, I could easily push the bullet past it with the seater, but if you wanna see concentric loaded rounds, this isn't the way to do it.

Anyhow, so at this point, you have to use an inside neck reamer to cut that whisker of brass out. Once it is gone, it's gone, it is a one time operation, but man, figuring it out put a few of us through the ringer. Anyhow, hope this is helpful to anyone neck brass down from a larger caliber.

Interestingly enough, my 35 Newton is formed out of 375 Ruger cases and doe not have any sign of a donut, SO it isn't a hard and fast rule you will always get one, but if you do, there is only one way to fix it.

Here is a picture of the pin gauges. Mine start from .250 and go up to .500.. I'll have to get a 2nd set of the small ones up to the .250 side. In reality, I need all of them in the middle of the two sets.. Oh well, they aren't alot of money but man have they schooled me on some things I'd never thought about.

Here are a couple of pictures of what I am talking about forming the donut without really knowing it is there.

There is a 300 Win on the left and a 7mm Mashburn on the right after going through the form and trim die..

This is a picture of a 160 Swift A-Frame that is stopped by the donut. The bullet will fall through the neck until it hits the donut and stop. Of course if I wanted to, I could easily push the bullet past it with the seater, but if you wanna see concentric loaded rounds, this isn't the way to do it.

Anyhow, so at this point, you have to use an inside neck reamer to cut that whisker of brass out. Once it is gone, it's gone, it is a one time operation, but man, figuring it out put a few of us through the ringer. Anyhow, hope this is helpful to anyone neck brass down from a larger caliber.

Interestingly enough, my 35 Newton is formed out of 375 Ruger cases and doe not have any sign of a donut, SO it isn't a hard and fast rule you will always get one, but if you do, there is only one way to fix it.