Aussie Wanderer

Beginner

- May 5, 2022

- 247

- 602

Hi Guys,

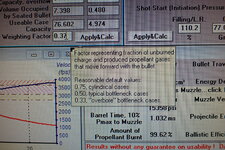

Hoping I can get a QL for a mate who is shooting a 257 weatherby. He is pushing the Barnes 101LRX at 3,840fps out of a 26 inch tube. This just wreaks of excessive pressure to me. He is loading 77 grains of H1000. Still shoots very accurately, but I am concerned there is a ticking time bomb close to his eyes and face.

Any help is much appreciated.

Thanks from the southern hemisphere ;-)

Hoping I can get a QL for a mate who is shooting a 257 weatherby. He is pushing the Barnes 101LRX at 3,840fps out of a 26 inch tube. This just wreaks of excessive pressure to me. He is loading 77 grains of H1000. Still shoots very accurately, but I am concerned there is a ticking time bomb close to his eyes and face.

Any help is much appreciated.

Thanks from the southern hemisphere ;-)