- Thread starter

- #41

jerbearyukon44

Beginner

- Jul 28, 2024

- 101

- 61

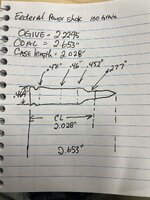

So I am getting a little frustrated.

I am using NEW Starline brass

100 grain nosler partions.

I am under SAMMI specs now ( pretty much mirrors the Federal Power-Shok bullets).

I can get the power shocks to chamber no problem but mine aren’t going in smoothly…. Can’t close it.

So I used a fired piece of brass that I did finally get to work and did the blue locktite trick to find the ogive and the COAL on my bore.

I sized some brass trimmed and seated the bullet back 20 thousands (.002) and it won’t chamber.

So then I tried the factory feds again no problem

So I made a bullet exactly the same as the fed and 2 out of three didn’t chamber.

WTH

Jer

I am using NEW Starline brass

100 grain nosler partions.

I am under SAMMI specs now ( pretty much mirrors the Federal Power-Shok bullets).

I can get the power shocks to chamber no problem but mine aren’t going in smoothly…. Can’t close it.

So I used a fired piece of brass that I did finally get to work and did the blue locktite trick to find the ogive and the COAL on my bore.

I sized some brass trimmed and seated the bullet back 20 thousands (.002) and it won’t chamber.

So then I tried the factory feds again no problem

So I made a bullet exactly the same as the fed and 2 out of three didn’t chamber.

WTH

Jer

Last edited: